- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

A Comprehensive Guide to Understanding Straight Seam Welded Pipes

0. What are Straight Seam Welded Pipes?

1. Characteristics of straight seam welded pipes

2. Classification of straight seam welded pipes

- 1. Straight seam submerged arc welded pipe: Straight seam submerged arc welded pipe (LSAW) is generally made of steel plate as raw material and undergoes different forming processes, using double-sided submerged arc welding and post-welding expansion to form welded pipes.

- 2. Straight seam high-frequency welded pipe: It is a welded pipe that uses high-frequency alternating current to heat the surface of the steel plate, quickly reaching the melting point and pressing to form. Compared with resistance welded pipes, high-frequency welded pipes have more stable quality, higher production efficiency, and a wider range of applications. The price of high-frequency welded pipes is slightly higher than that of resistance welded pipes.

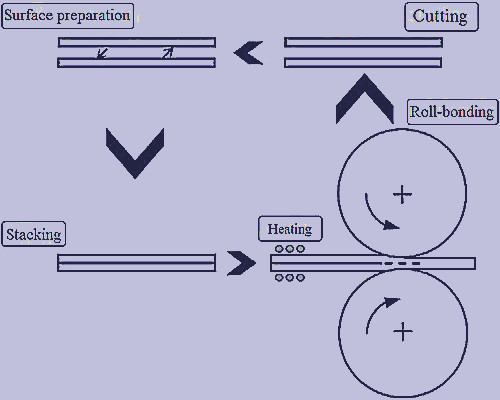

3. Production process of straight seam steel pipes

3.1 Longitudinal submerged arc welded steel pipes (LSAW)

3.1.1 Submerged arc welding process

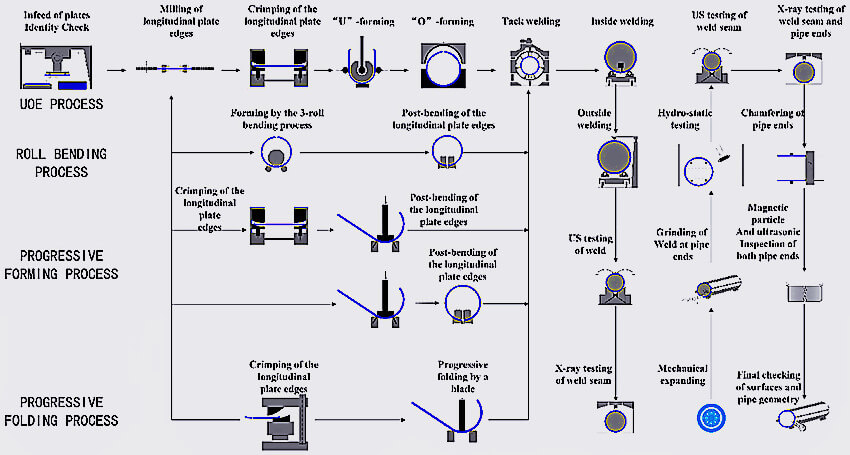

Schematic illustration of the most important steps in the manufacture of LSAW pipes (Image from: researchgate.net)

- Plate detection: After the steel plate used to manufacture large-diameter submerged arc welded straight seam steel pipes enters the production line, the entire plate is first subjected to ultrasonic inspection;

- Edge milling: Double-sided milling is performed on the two edges of the steel plate using an edge milling machine to achieve the required plate width, edge parallelism, and groove shape;

- Pre-bending edge: Use a pre-bending machine to pre-bend the edge of the steel plate so that the edge has the required curvature;

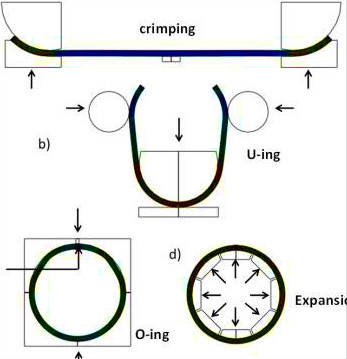

- Forming: On the JCO molding machine, the first half of the pre-bent steel plate is stamped multiple times to form a "J" shape, then the other half of the steel plate is also bent to form a "C" shape, and finally an open "O" shape is formed

- Pre welding: Make the formed straight seam welded steel pipe joint and use gas shielded welding (MAG) for continuous welding;

- Internal welding: Use longitudinal multi wire submerged arc welding (up to four wires) to weld the inner side of the straight seam steel pipe;

- External welding: longitudinal multi wire submerged arc welding is used to weld the outer side of the straight seam submerged arc welded steel pipe;

- Ultrasonic inspection I: 100% inspection of the internal and external welds of straight seam welded steel pipes and the base metal on both sides of the welds;

- X-ray inspection I: Conduct 100% X-ray industrial television inspection of internal and external welds, using an image processing system to ensure the sensitivity of the inspection;

- Expanding: Expanding the entire length of submerged arc welded straight seam steel pipes to improve the dimensional accuracy of the pipes and improve the distribution of internal stress in the pipes;

- Hydrostatic test: Inspect the expanded steel pipes one by one on a hydraulic testing machine to ensure that they meet the required test pressure. The machine has automatic recording and storage functions;

- Chamfering: Process the qualified steel pipe at the pipe end to meet the required pipe end groove size;

- Ultrasonic inspection II: Conduct ultrasonic inspection one by one again to inspect the defects that may occur in the straight seam welded steel pipe after expansion and water pressure;

- X-ray inspection II: Conduct X-ray industrial television inspection and take photos of pipe end welds on steel pipes after expansion and hydraulic testing;

- Pipe end magnetic particle inspection: Conduct this inspection to discover pipe end defects;

- Corrosion prevention and coating: Qualified steel pipes shall undergo corrosion prevention and coating according to user requirements.

Manufacturing process for straight seam welded pipe

Pipe manufacturing process and main equipment

Steel plate → Vacuum lifting → Ultrasonic testing of steel plate → Milling → Pre bending

J forming → C forming → O forming

After the conveyor roller transports the steel plate to the oil pressure bed for positioning, the first time 1/3 of the width of the plate is formed by the upper and lower molds, which is called "J forming"; The other end of the second molding is 1/3 of the board width, known as "C-molding"; Finally, the remaining 1/3 of the board width is formed from the center of the board, resulting in a circular tube shape called "O forming".

a) "O" stamping forming b) "C" stamping forming c) "J" stamping forming

Figure.3 Schematic diagram of UO (UOE) forming process

Figure.4 Schematic diagram of RB (RBE) forming process

Comparison of JCO and UO molding methods:

JCO forming is a progressive pressure forming process that transforms the forming process of steel pipes from two steps of UO forming to multiple steps. During the forming process, the steel plate undergoes uniform deformation, low residual stress, and no scratches on the surface. The processed steel pipe has greater flexibility in the size range of diameter and wall thickness, which can produce both large and small batches of products; It can produce both large-diameter high-strength thick walled steel pipes and small-diameter large walled thick steel pipes; Especially in the production of high steel grade thick walled pipes, especially small and medium-sized thick walled pipes, it has advantages that cannot be compared to other processes. It can meet more requirements of users in terms of steel pipe specifications. Low investment, but low production efficiency, with a typical annual output of 100000 to 250000 tons.

UO molding, using two pressure forming processes of U and O, is characterized by high capacity and high output, typically reaching an annual output of 300000 to 1 million tons, suitable for large-scale production of a single specification. The investment is large and generally difficult for developing countries to bear.

Ultrasonic inspection equipment: Ultrasonic inspection of the weld bead is required before and after the water pressure test.

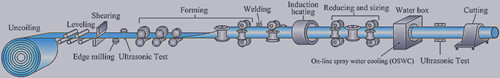

3.2 Straight seam high-frequency resistance welded steel pipes (ERW)

High frequency straight seam welded steel pipe, also known as straight seam resistance welded pipe, is generally produced with a smaller diameter, usually below DN600. Large diameter steel pipes are generally double-sided submerged arc welded. Its characteristics are: high welding speed, small welding heat affected zone, no cleaning of the workpiece during welding, and welding of thin-walled pipes.

3.2.1 Comparison between longitudinal high-frequency resistance welded steel pipe (ERW) and longitudinal submerged arc welded steel pipe (UOE)

1) Differences in raw materials and production capacity

The raw material of ERW steel pipe is hot-rolled steel coil, while the raw material of UOE steel pipe is cold-rolled steel plate. Therefore, ERW steel pipes can achieve continuous assembly line operations with high production efficiency and low production costs; UOE steel pipes are processed using steel plates, which cannot achieve continuous assembly line operations, resulting in low production efficiency and high production costs.

2) Welding differences

ERW steel pipe welding does not require the addition of welding wires; UOE steel pipes require the addition of welding wires.

3) Product differentiation

ERW steel pipes are limited by the thickness of the steel coil, with a maximum thickness of 25mm and a maximum diameter of 660mm that can be produced; The maximum thickness that UOE steel pipes can produce is 40mm, and the maximum diameter that can be produced is only limited by the width of the steel plate. Currently, the maximum diameter that can be produced is 1422mm.

4) Application differences

ERW steel pipes are mainly used in long-distance land pipelines such as natural gas, refined oil, crude oil, and mineral slurry. UOE steel pipes are mainly used in high-pressure subsea long-distance pipelines, high-altitude cold areas, etc.

3.2.2 Pipe making equipment and manufacturing processes of straight seam high-frequency resistance welded steel pipes

Uncoiling → Leveling → Shear Butt Welding → Looper Storage → Plate Exploring → Trimming → Roller Forming → High Frequency Welding → Removing Inner and Outer Burrs → Online Ultrasonic Testing → Intermediate Frequency Annealing → Air Cooling → Water Cooling → Sizing → Straightening → Cutting → Initial Inspection of Dimensions and Appearance → End Repair → Hydrostatic Testing → Full Pipe Ultrasonic Testing → Offline Weld Ultrasonic Testing → Pipe End Ultrasonic Testing → Final Inspection of Dimensions and Appearance → Application of Anti-rust Paint → Spray Marking → Pipe End Protection → Comprehensive Inspection And warehousing.

The uncoiler, leveling machine, shear welding machine, and storage bin are essential equipment for the uninterrupted supply of steel strips to the forming machine and improving production efficiency.

Cutting and butt welding machine: Cut and butt the tail of the previous steel coil with the head of the subsequent steel coil.

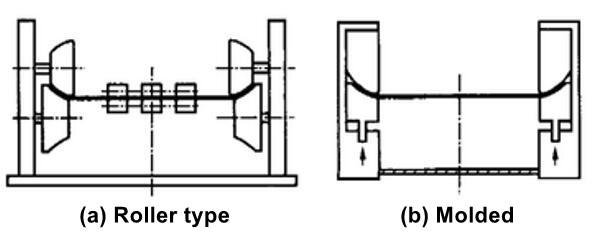

Loop storage device: The loop is an indispensable and important equipment to ensure the automatic production of high-frequency straight seam welded pipes, playing a role in ensuring the storage, supply, and continuous operation of the main rolling mill. As shown in the following figure.

Figure.5 High frequency welding loop material storage device

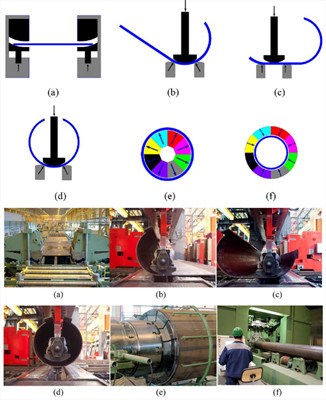

Forming process (rolling tube): The deformation of the plate in the process of forming the tube is mainly manifested in two aspects: continuous transverse and longitudinal, and the constraint force applied on it is implemented through two aspects: the roll pass and the arrangement of the rolling mill. The roll pass causes transverse deformation of the steel plate, and the rolling mill arrangement causes longitudinal deformation of the steel plate. The following figure shows the forming process of welded pipes.

Figure.6 Schematic diagram of welded pipe forming process

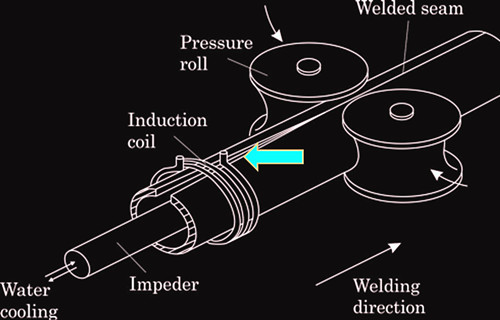

High frequency welding: By utilizing the skin effect of high-frequency current, high-frequency electrical energy can be concentrated on the surface of the welding piece, and by utilizing the proximity effect, the position and range of the high-frequency current flow path can be controlled. When high frequency current is required to be concentrated in a certain part of the weldment, this requirement can be achieved by forming a current circuit between the conductor and the weldment and making the conductor close to this part of the weldment so that they form adjacent conductors with each other. High frequency welding is based on the specific form and special requirements of the weldment structure, mainly using the skin effect and proximity effect to quickly heat the surface metal of the weldment to be welded and achieve welding. As shown in the following figure.

Figure.7 Schematic diagram of high-frequency welding

4. Inspection methods for straight seam welded pipes

There are many methods for quality inspection of straight seam welded pipes, among which the physical method is also the most commonly used inspection method. Physical inspection is a method that uses some physical phenomena for measurement or inspection. The inspection of internal defects in materials or Q235B straight seam welded pipes is generally carried out using non-destructive testing methods. The current non-destructive testing methods include magnetic testing, ultrasonic testing, radiographic testing, penetration testing, etc.

- Magnetic inspection: Magnetic testing can only detect defects on the surface and near surface of straight welded pipes, and quantitative analysis can only be conducted on defects. The nature and depth of defects can only be estimated based on experience. Magnetic inspection is the use of magnetic field magnetization to detect defects in Q235B straight seam welded pipes, resulting in magnetic leakage. According to the different methods of measuring magnetic flux leakage, it can be divided into magnetic particle method, magnetic induction method, and magnetic recording method, with magnetic particle method being the most widely used.

- Penetrant testing: Penetrant testing is the use of physical properties such as the permeability of certain liquids to detect and display defects, including dye penetrant testing and fluorescent testing. It can be used to inspect defects on the surface of ferromagnetic and non ferromagnetic materials.

- Radiographic inspection: Radiographic inspection is a method of detecting defects by utilizing the characteristics of radiation that can penetrate and attenuate in the material. According to the different types of radiation used for inspection, it can be divided into X-ray inspection γ There are three types of radiographic testing and high-energy radiographic testing. Due to the different methods of displaying defects, each type of radiographic inspection is divided into ionization method, fluorescent screen observation method, photography method, and industrial television method. Radiographic inspection is mainly used to inspect defects such as cracks, incomplete penetration, porosity, and slag inclusion inside the weld seam of Q235B straight seam welded pipe.

- Ultrasonic testing: Ultrasonic waves can be used for the inspection of internal defects in metals and other uniform media due to their reflection at the interfaces of different media. Ultrasound can detect defects in any welding material or any part, and can sensitively detect the location of defects. However, it is difficult to determine the nature, shape, and size of defects. Therefore, ultrasonic testing of Q235B straight seam welded pipes is often used in conjunction with radiographic testing.

5. The purpose of straight seam welded pipes

The use of straight seam welded pipes is very extensive, mainly including the following aspects:

- 1. Construction field: Straight seam welded pipes are often used for supporting, framing, and column parts of building structures, such as stairs, bridges, overpasses, and underground pipelines.

- 2. Oil and natural gas industry: Straight seam welded pipes are mainly used for transporting oil, natural gas, and other liquids or gases. They can be used for oil pipelines, natural gas pipelines, oil well pipelines, water injection well pipelines, etc.

- 3. Water and sewage systems: Straight seam welded pipes are also widely used in water and sewage systems, such as water supply pipelines, drainage pipelines, sewers, and rainwater pipelines.

- 4. Heat exchangers and boilers: Straight seam welded pipes are used as heat transfer media in heat exchangers and boilers, for heating or cooling liquids or gases.

- 5. Medical instruments and devices: Straight seam welded pipes are used in the medical industry to manufacture medical instruments and devices, such as infusion pipelines, developer delivery systems, etc.

Overall, straight seam welded pipes have good strength and durability, and are widely used in various engineering and industries to meet the needs of conveying and discharging liquids and gases.

6. Comparison between straight seam welded pipes and spiral welded pipes

Spiral welded pipes generally have higher strength than straight seam welded pipes, and can produce larger diameter welded pipes using narrower billets. Additionally, welded pipes with different diameters can be produced using billets of the same width. However, compared to straight seam pipes of the same length, the weld length increases by 30-100% and the production speed is lower. Therefore, smaller diameter welded pipes mostly use straight seam welding, while larger diameter welded pipes mostly use spiral welding.

6.1 Comparison of welding processes

The production process of straight seam steel pipes is relatively simple, mainly including high-frequency straight seam welded pipes and submerged arc welded straight seam welded pipes. High frequency straight seam welding of steel pipes is achieved by rolling a certain specification of long steel strip into a circular tube through a high-frequency welding machine and welding the straight seam. High frequency welding is a type of induction welding (or pressure contact welding) that does not require weld filler material, has no welding spatter, narrow welding heat affected zone, beautiful welding shape, and good welding mechanical properties. Therefore, it is widely used in the production of steel pipes. Connected into a steel pipe. The shape of steel pipes can be circular, square or irregular, depending on the sizing and rolling after welding. Straight seam welded pipe has high production efficiency, low cost, and rapid development. The straight seam submerged arc welded steel pipe has one longitudinal weld seam, and both the inner and outer welds are welded using one submerged arc welding process. After overall mechanical expansion treatment, the internal stress of the steel pipe is small and evenly distributed, which can effectively prevent stress corrosion cracking. The dimensional accuracy is high, and it is convenient for on-site welding construction. The process of pre welding and fine welding is adopted, which ensures stable welding process and high weld quality. Welds are easy to achieve non-destructive testing during production and field non-destructive testing during use. The product has a wide range of specifications, which can produce both small diameter and large wall thickness steel pipes. The pipe diameter is limited by the width of the steel plate, and a steel plate of one width can only produce a steel pipe of one diameter.

The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. Spiral seam submerged arc welded pipes do not have 100% ultrasonic testing of the base material, expansion and other processes, resulting in low production and difficulty in automatic tracking of welds. Forming and welding are all completed under continuous dynamic operation; Continuous production can be achieved, and larger diameter welded pipes can be produced using narrower billets. Welded pipes with different diameters can also be produced using billets of the same width. However, compared to straight seam pipes of the same length, the weld length increases by 30-100% and the production speed is lower. Therefore, smaller diameter welded pipes mostly use straight seam welding, while larger diameter welded pipes mostly use spiral welding.

In terms of welding process, the welding method for spiral welded pipes and straight seam steel pipes is the same (submerged arc welding), but straight seam welded pipes inevitably have many T-shaped welds, which greatly increases the probability of welding defects. Moreover, the welding residual stress at the T-shaped weld is relatively high, and the weld metal is often in a three-dimensional stress state, increasing the possibility of cracks.

In China, smaller diameter welded steel pipes mostly use straight seam welding, while larger diameter welded steel pipes mostly use spiral seam welding. Currently, China has the ability to produce large diameter straight seam submerged arc welded steel pipes and has been used in oil and gas transportation projects.

6.2 Comparison of Material Properties

Straight seam submerged arc welded pipes are produced from steel plates, while spiral welded pipes are produced from hot-rolled coils. The rolling process of the hot rolled strip mill has a series of advantages, including the ability to obtain metallurgical processes for producing high-quality pipeline steel. For example, a water cooling system is installed on the output stage to accelerate cooling, which allows the use of low alloy components to achieve special strength levels and low-temperature toughness, thereby improving the weldability of the steel. But this system is basically not available in steel plate production plants. The alloy content (carbon equivalent) of coil plates is often lower than that of similar grade steel plates, which also improves the weldability of spiral welded pipes. It should be noted that due to the fact that the rolling direction of the spiral welded pipe is not perpendicular to the axis of the steel pipe (its clamping depends on the spiral angle of the steel pipe), and the rolling direction of the steel plate of the straight seam steel pipe is perpendicular to the axis of the steel pipe, the crack resistance performance of the spiral welded pipe material is better than that of the straight seam steel pipe.

Moreover, according to the process regulations of submerged arc welding, each weld seam should have a starting and extinguishing point, but each straight seam welded pipe cannot meet this condition when welding the circumferential seam, so there may be many welding defects at the extinguishing point.

6.3 Comparison of structural strength

When welded pipes are subjected to internal pressure, they usually generate two main stresses on the pipe wall, namely radial stress and axial stress, and the weld joint is subjected to composite stress. Due to the different shapes of the weld seam, the combined stress at the spiral weld seam is 60-85% of the main stress of the straight welded pipe when subjected to internal pressure. Therefore, under the same working pressure, the wall thickness of spiral welded pipes with the same diameter can be reduced compared to straight welded pipes.

6.4 Quality Comparison and Analysis

6.4.1 Advantages and disadvantages of spiral seam submerged arc welded pipes

Disadvantages of spiral seam submerged arc welded steel pipes

- (1) Without 100% non-destructive testing of the base material, it is difficult to ensure the internal quality of the pipe body.

- (2) The probability of defects in T-shaped welds is high.

- (3) The welded pipe production line is relatively long, resulting in many defects such as base material indentation and scratches.

- (4) The dynamic production conditions of forming while welding are prone to edge misalignment, seam opening, pipe diameter changes, and the influence of dynamic conditions combined with the position of welding points on spatial surfaces, which can easily lead to various welding defects.

- (5) There are complex residual stresses, such as bending stress, twisting stress, and sufficient deformation of the free edge during the forming and curling process, stress generated by forced deformation of the delivery edge, and residual stress generated by internal and external welding. The distribution and magnitude of residual stresses vary greatly, and spiral welded pipes are difficult to eliminate residual stresses, thus affecting the service life of pipelines.

- (6) The weld length, which is 1.3 to 2.3 times the pipe length, increases the probability of defects.

- (7) The welding speed is high, and the probability of welding defects is high.

- (8) When transporting acidic natural gas, it can damage the submerged arc welding seam.

Advantages of spiral seam submerged arc welded pipes

- (1) Due to the anisotropy of the impact value, the maximum driving direction of its cracking avoids the minimum fracture resistance direction.

- (2) Due to the anisotropy of strength, the direction of weak strength perpendicular to the spiral weld avoids the direction of main stress.

6.4.2 Advantages and disadvantages of straight seam submerged arc welded pipes

Disadvantages of straight seam submerged arc welded pipes

- (1) The direction of main stress is consistent with the direction of strength weakness of the vertical weld seam.

- (2) The maximum driving direction of cracking is consistent with the minimum fracture resistance direction.

Advantages of straight seam submerged arc welded pipes

- (1) 100% ultrasonic testing of the base material ensures the internal quality of the pipe body.

- (2) There is no unwinding - the process of disc shearing, resulting in less material indentation and scratches.

- (3) Welding is carried out in a straight line in a horizontal position after forming, therefore, the control of misalignment, seam opening, and pipe diameter circumference is good, and the welding quality is excellent.

- (4) After stress relief, there is basically no residual stress in the finished pipe.

- (5) The weld seam is short and the probability of defects is low.

- (6) It is possible to transport humid acidic natural gas with conditions.

- (7) After expansion, the geometric dimension accuracy of the steel pipe is high, greatly facilitating on-site butt welding of the pipeline and improving the quality of the entire pipeline.

6.5 Summary:

- (1) The manufacturing process of spiral steel pipes determines that their residual stress is relatively high. According to relevant foreign records, some even approach the yield limit. Due to the use of expansion technology, the residual stress of straight seam submerged arc welded steel pipes is close to zero.

- (2) Spiral weld seam welding tracking and ultrasonic online detection tracking are both difficult, therefore, the probability of weld defects exceeding the standard is higher than that of straight seam submerged arc welded pipes.

- (3) The misalignment of spiral steel pipe welds is mostly between 1.1 and 1.2mm, and according to international practice, the misalignment should be less than 10% of the thickness. If the pipe wall thickness is small, the misalignment cannot meet the requirements, while straight seam submerged arc welded pipes do not have this problem.

- (4) Compared with straight seam submerged arc welded pipes, the flow line of spiral welds is poor and the phenomenon of stress concentration is severe

- (5) The heat affected zone of spiral submerged arc welded steel pipes is larger than that of straight seam submerged arc welded steel pipes, and the heat affected zone is the weak link in the quality of welded pipes.

- (6) The poor geometric accuracy of spiral seam welded steel pipes poses certain difficulties for on-site construction (such as alignment and welding).

- (7) The thickness that spiral seam welded steel pipes can achieve with the same diameter is much smaller than that of straight seam submerged arc welded steel pipes.

7. How to purchase straight seam welded pipes?

In today's rapidly developing industrial market, purchasing straight seam welded pipes is an essential part of many industries. Whether in the construction, manufacturing, or oil and gas industries, straight seam welded pipes play a crucial role. To ensure that you can obtain the highest quality products and meet the needs of the project, it is crucial to understand how to purchase straight welded pipes effectively.

1. Determine requirements and specifications

Before purchasing straight seam welded pipes, it is necessary first to clarify the specific requirements and specifications of the project or business. This includes the size, material, thickness, and required quantity of the pipeline. Understanding these key elements will help you better communicate with suppliers and choose the product that best suits your needs.

2. Looking for reputable suppliers

Choosing a reputable supplier is a crucial step in ensuring high-quality straight seam welded pipes are obtained. You can evaluate its credibility by referring to customer reviews, industry reputation, and supplier certification qualifications. Communicate with multiple suppliers to understand their product quality, delivery time, after-sales service and make trade-offs.

3. Considering product quality and certification

Ensuring that straight seam welded pipes comply with international and industry standards is an important aspect of ensuring engineering quality. Choosing products that comply with ISO 9001 quality management system certification will help ensure that you receive high-quality products. At the same time, understanding the supplier's quality management system and product quality control process is also a crucial step.

- Appearance inspection: Accurately measure the thickness of thick walled straight seam welded pipes. If the wall thickness of the steel pipe is not enough, the gate method should be used. If a hammer protects the end of the steel pipe, it may appear thick on the appearance, but in fact, using instruments to measure it will expose its shortcomings.

- Inspect the joints and joints of welded pipes: use ultrasonic testing, radiographic testing, penetrant testing, and magnetic testing to conduct inspections without damaging the product.

- Strength testing of pressure vessels: In addition to sealing testing, strength testing must be conducted on pressure vessels. The most commonly used are hydraulic and pneumatic tests. Pneumatic testing is faster and more sensitive than hydraulic testing, but it can also be more dangerous. Therefore, during the operation process, it is necessary to follow safety technical measures to prevent accidents from occurring.

- Tightness testing: For welded containers that store gas or liquid, if there are nondense defects in the weld seam of the steel pipe, such as pores, cracks, loose structure, incomplete penetration, etc., water carrying test, water flushing test, kerosene test, etc. can be used for testing.

- Hydrostatic test: Each steel pipe must undergo a hydrostatic test without any seepage phenomenon.

4. Consider delivery time and logistics arrangements

Timely delivery and good logistics arrangements are crucial when purchasing straight seam welded pipes. Confirm the production cycle, delivery time, and transportation method of the product with the supplier, and ensure that they can deliver the product on time. Meanwhile, for large-scale engineering projects, reasonable planning of logistics arrangements is also one of the important factors to ensure the smooth progress of the project.

5. Price comparison and negotiation skills

Price is one of the important factors that must be addressed in the procurement process. When considering the procurement cost of straight seam welded pipes, it is recommended to compare prices with multiple suppliers and comprehensively consider different factors such as product quality and delivery time. Mastering certain negotiation skills and actively communicating and negotiating with suppliers on prices, delivery conditions, and other aspects can help you obtain more competitive prices and more favorable procurement conditions.

We cannot blindly pursue low prices and diverse comparisons. If low-quality steel pipes are used for a long time, they may rust, crack, and other unsafe situations. So, cost-effectiveness is a key factor that we need to consider.

How to control the price when purchasing straight seam welded pipes?

Straight seam welded pipe is a widely used steel pipe product. When purchasing straight seam welded pipes, controlling the price is crucial. Therefore, here, we share some tips on controlling the price of straight seam welded pipes and improving procurement efficiency.

- Budget: It is very important to set a budget before purchasing straight seam welded pipes. Budgeting can help you understand your financial situation and help you control expenses during the purchasing process. At the same time, budgeting can also help you choose products more wisely.

- Price comparison: It is very important to compare prices when selecting suppliers and products. Engage with multiple suppliers as much as possible and understand their prices, quality, and production capabilities. Comparing prices can help you find straight seam welded pipes with high cost-effectiveness.

- Research: It is necessary to conduct sufficient research before selecting straight seam welded pipes. The research process can not only help you understand product quality and market prices but also help you understand the advantages and disadvantages of different specifications and materials.

- Communication: Establish good communication with different suppliers during the procurement process. Communication can help you understand supplier product information, transportation methods, prices, and delivery times. In addition, establishing a good relationship with suppliers can help you obtain better discounts when purchasing.

- Adopting procurement strategies: Mastering different procurement strategies is also very useful. For example, group buying can help you get discounts on prices, while long-term cooperation can earn regular discounts.

6. After-sales service and warranty terms

Ensuring that suppliers provide good after-sales service and reasonable warranty terms is an important link in ensuring procurement quality and subsequent maintenance. Communicate clearly with suppliers about after-sales service policies, product warranty periods, and after-sales support measures, which will bring more convenience and guarantee for your subsequent use and maintenance.

In summary, by reasonably planning the procurement process, selecting reputable suppliers, ensuring product quality and delivery time, flexibly using negotiation skills, and paying attention to after-sales service and warranty terms, you will be able to purchase high-quality straight seam welded pipes that meet the requirements more efficiently, and inject stable support and guarantee into your engineering project.

Where to purchase straight seam welded pipes?

When purchasing straight seam welded pipes, you can consider yaang. As a manufacturer of straight welded pipes, yaang have the following advantages:

- High quality products: Our straight seam steel pipes have undergone strict quality control and certification to ensure stable and reliable product quality. We adopt advanced production processes and high standard raw materials, committed to providing you with high-quality product solutions.

- Competitive pricing: We strive to optimize production costs and provide you with competitive pricing strategies through economies of scale and efficient operations. We believe that reasonable pricing can help you improve market competitiveness and gain greater profit margins.

- Customized service: We value customers' personalized needs and can customize straight seam steel pipes of different specifications and materials according to your specific requirements. Our flexible production capacity will ensure that you receive customized products that fully meet the needs of your project.

- Fast delivery: We focus on the accuracy and speed of delivery time to ensure that you receive the required straight seam steel pipes on time. Our efficient logistics system and excellent order processing process will provide strong support for your business operations.

- Comprehensive after-sales service: In addition to providing high-quality products, we also provide comprehensive after-sales service and technical support. Our professional team will provide you with professional technical guidance and problem-solving solutions to ensure that you receive the best support and assistance during use.

Choosing yaang's straight seam steel pipes not only saves costs and improves efficiency but also ensures the smooth progress of your engineering project. We look forward to working with you to create a better future together!

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.