- SITEMAP

- CONTACT US

- 8618267732328

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

904L Stainless Steel Seamless Pipe Non-stabilised Low Carbon For Pressure Vessels

- FOB PriceUSD 800 - 30,000/Piece

- PortNingbo or Shanghai

- MOQ0.5 Tons

- Supply Ability1000 Tons Per Month

- Payment TermsL/C,T/T,Western Union

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 15 days

Quick Detail:

Name: 904L Stainless Steel Seamless Pipe Non-stabilised Low Carbon For Pressure Vessels

Place of Origin:Zhejiang, China (Mainland) Brand Name: Yaang

Shape: Seamless Stainless Steel Pipe Material: stainless steel

Steel Grade: 904L...

Packaging & Delivery

| Packaging Detail: | according to customer's require or export's standard |

| Delivery Detail: | 2 - 15 days after confirmation |

Specifications Of Stainless Steel Seamless Pipe:

904L is a non - stabilised low carbon high alloy austenitic stainless steel. The addition of

copper to this grade gives it greatly improved resistance to strong reducing acids,

particularly sulphuric acid. It is also highly resistant to chloride attack - both pitting /

crevice corrosion and stress corrosion cracking. This grade is non - magnetic in all

conditions and has excellent weldability and formability. The austenitic structure also gives

this grade excellent toughness, even down to cryogenic temperatures. 904L does have very

substantial contents of the high cost ingredients nickel and molybdenum. Many of the

applications in which this grade has previously performed well can now be fulfilled at lower

cost by duplex stainless steel 2205 (S31803 or S32205), so it is used less commonly than in

the past.

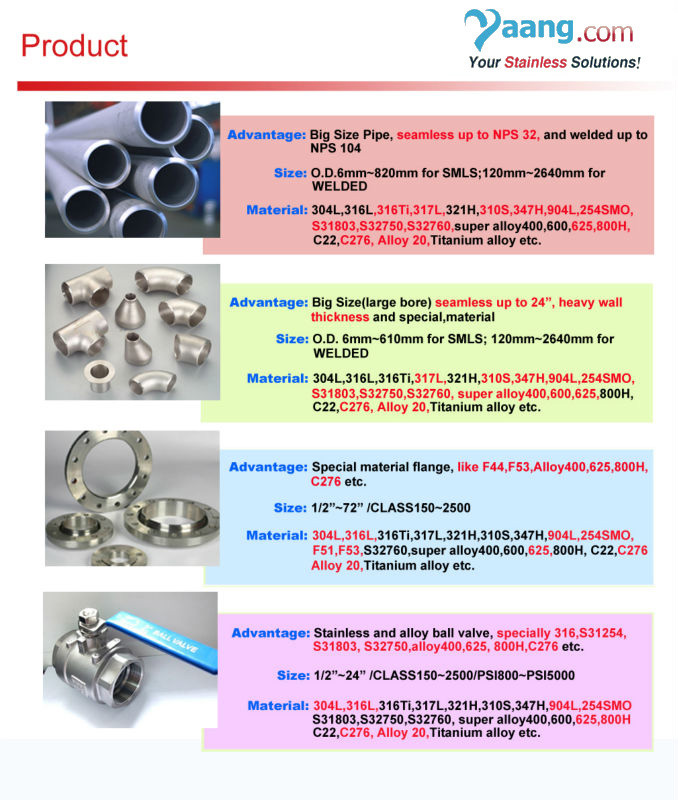

904L Stainless Steel Pipes and Tubes Product Range

904L Stainless Steel Pipes and Tubes Specifications: ASTM A/ASME SA 269/677 904L Stainless Steel Pipes and Tubes Sizes

(Seamless): 1/2" NB - 8" NB

904L Stainless Steel Pipes and Tubes Sizes (ERW): 1/2" NB - 24" NB

904L Stainless Steel Pipes and Tubes Sizes (EFW): 6" NB - 100" NB

904L Stainless Steel Pipes and Tubes Wall Thickness available:

Schedule 5S - Schedule XXS (heavier on request)

904L Stainless Steel Pipes and Tubes Other Materials Testing:

NACE MR0175, H2 SERVICE, OXYGEN SERVICE, CRYO SERVICE, etc

These properties are specified for flat rolled product (plate, sheet and coil) in ASTM B625. Similar but not necessarily identical properties are specified for other products such as pipe, tube and bar in their respective specifications

Corrosion Resistance

Although originally developed for its resistance to sulphuric acid it also has a very high resistance to a wide range of

environments. A PRE of 35 indicates that the material has good resistance to warm sea water and other high chloride

environments. High nickel content results in a much better resistance to stress corrosion cracking than the standard austenitic grades. Copper adds resistance to sulphuric and other reducing acids, particularly in the very aggressive "mid concentration" range.

In most environments 904L has a corrosion performance intermediate between the standard austenitic grade 316L and the very highly alloyed 6% molybdenum and similar "super austenitic" grades.

In aggressive nitric acid 904L has less resistance than molybdenum - free grades such as 904L and 310L.

For maximum stress corrosion cracking resistance in critical environments the steel should be solution treated after cold work.

Heat Resistance

Good resistance to oxidation, but like other highly alloyed grades suffers from structural instability (precipitation of brittle

phases such as sigma) at elevated temperatures. 904L should not be used above about 400C.

Heat Treatment

Solution Treatment (Annealing) - heat to 1090 - 1175C and cool rapidly. This grade cannot be hardened by thermal treatment.

Welding

904L can be successfully welded by all standard methods. Care needs to be taken as this grade solidifies fully austenitic, so is susceptible to hot cracking, particularly in constrained weldments. No pre - heat should be used and in most cases post weld heat treatment is also not required. AS 1554.6 pre - qualifies Grade 904L rods and electrodes for welding of 904L.Fabrication

904L is a high purity, low sulphur grade, and as such will not machine well. Despite this the grade can be machined using

standard techniques.

Bending to a small radius is readily carried out. In most cases this is performed cold. Subsequent annealing is generally not

required, although it should be considered if the fabrication is to be used in an environment where severe stress corrosion

cracking conditions are anticipated.

APPLICATIONS FIELD :

|

Industry |

Applications |

Industry |

Applications |

|

Chemical |

Heat Exchanger, Boiler |

Sugar |

Evaporators, Condensers, Driers |

|

Petrochemicals |

Condensers |

Automobiles |

Muffler Tubes Hydraulic Tubing |

|

Refineries |

General Piping |

Construction |

Architectural Furniture |

|

Fertilizers |

Pressure Vessels |

Pharmaceuticals, Dairy, Food & Beverages |

Machineries Process Piping |

|

Paper & Pulp |

Industrial Equipments |

Submersible Pumps |

Pump Casing Applications |

|

Engineering |

Machineries Instrumentation Tubing |

|

|

If any inquiry about products, please feel free to contact us [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.