Packaging & Delivery

| Packaging Details: | Wooden case or under customer's request |

|---|---|

| Delivery Detail: | 2-10 days |

PRODUCTS

Credibility ,

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

| Packaging Details: | Wooden case or under customer's request |

|---|---|

| Delivery Detail: | 2-10 days |

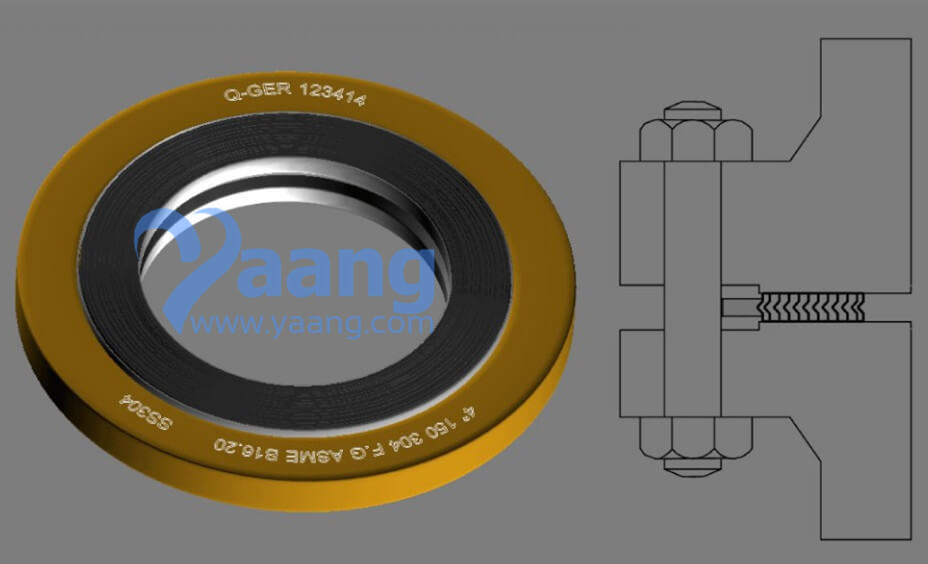

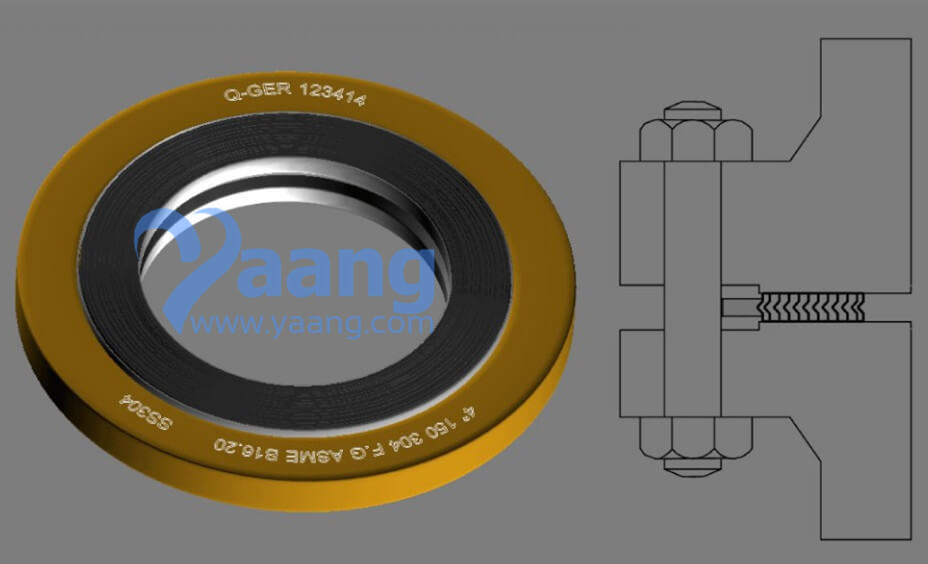

ASME B16.20 SS304 Graphite Spiral Wound Gasket 4 Inch

Material: Stainless Steel 304

FILLING: Graphite

Size: 4 inch

The Stainless Steel Spiral Wound Gasket adopts high-quality SUS304 or SUS316

("V" or "W"shape) metal strips, other alloy materials and some flexible materials like graphite,

asbestos, PTE and non-asbestos, which are overlapped and wound spirally with each other.

The metal strips are fixed on the initial and terminal ends by means of spot welding.

The metal spirally-wound gasket has the best resilien ce among the semi-metal hermetic gaskets.

Its structural density can be made subject to different locking forces.

Also the internal and external steel rings can be used to control its maximum compaction.

It's not demanding for the surface precision of the flange sealing surface contacting the

spirally-wound gasket. It's especially applicable for such occasions as uneven load, slack joint,

periodical changes of temperature and pressure, impact or vibration.

It's an ideal static seal element for flange connection in valves, pumps, heat exchangers, towers, manholes,handholes and so on.

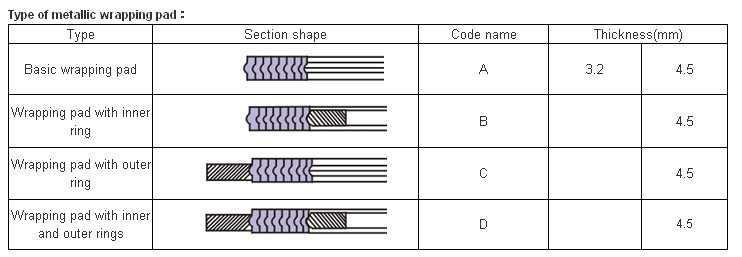

Structural material of metallic wrapping pad:

| Filling | Steel band | Inner ring | Outer ring |

| Asbestos wrapping | SUS 304 | Carbon steel | Carbon steel |

| Graphite wrapping | SUS 316 | SUS 304 | SUS 304 |

| Teflon wrapping | SUS 316L | SUS 316 | SUS 316 |

| SUS 316L | SUS 316L |

| Filling | Temperature(℃) | Max operating pressure(kg/cm2) |

| Asbestos wrapping | -200~550 | 250 |

| Graphite wrapping | -150~450 | 100 |

| Teflon wrapping | 240~260 | 100 |

| Flange type | Spiral wound gasket form |

| Flat face flange(F.F) | Wrapping pad with outer ring only |

| Wrapping pad with inner and outer rings | |

| Raised face flange(R.F) | Wrapping pad with outer ring only |

| Wrapping pad with inner and outer rings | |

| Male and female flange(M & F) | Basic wrapping pad |

| Wrapping pad with inner ring only | |

| Tongue and groove flange(T & F) | Basic wrapping pad |

| Wrapping pad with inner ring only | |

| Flat and groove flange(F & G) | Basic wrapping pad |

| Wrapping pad with inner ring only |

| Wrapping pad coefficient | m=2.5-4 |

| Wrapping pad service pressure | ≤25MPa |

| Wrapping pad service temperature | -196℃-700℃(Oxidizing medium no higher than 600℃) |

| Wrapping pad minimum pretension specific pressure | y=68MPa |

Application

Spiral Wound Gasket of flange connection in pipelines, valves, pressure containers,

condensers, heat exchangers, towers, manholes, handholes and so on in such industries

as petroleum, chemical engineering, metallurgy, electricity, shipping and machinery.

If any inquiry, please feel free contact by email [email protected]

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.