- SITEMAP

- CONTACT US

- 8618267732328

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

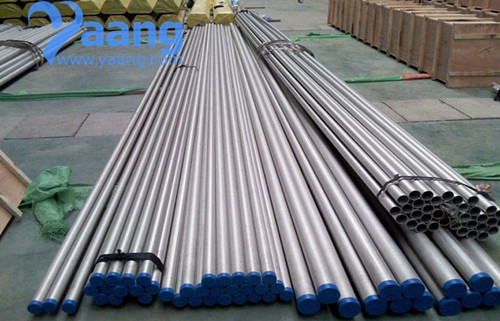

ASTM A213 TP316Ti Stainless Steel Seamless Pipe , UNSS31635 1.4571 Seamless Tube

- FOB PriceUSD 800 - 30,000/Piece

- PortNingbo or Shanghai

- MOQ0.5 Tons

- Supply Ability1000 Tons Per Month

- Payment TermsL/C,T/T,Western Union

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 15 days

Quick Detail:

Name: ASTM A312 A213 Cold Drawn Seamless Pipe, TP304 304L Stainless Steel Tubing

Place of Origin:Zhejiang, China (Mainland) Brand Name: Yaang

Shape: Seamless Stainless Steel Pipe Material: stainless steel

Steel Grade: 316Ti (UNS S31635)/A213 ...

Packaging & Delivery

| Packaging Detail: | according to customer's require or export's standard |

| Delivery Detail: | 2 - 15 days after confirmation |

Specifications:

| Material Grade: | 316Ti (UNS S31635) | Outer Diameter: | 6mm - 830mm |

| Standard: | EN10216 - 5, EN10216 - 2, DIN 17456, DIN 17458, ASTM A312, A213, A269, A511, A789, A790 ETC, GOST 9941, JIS G3459 |

Surface: | Solid Annealed/Pickling/180# 240# 320# 400# |

| Type: | Stainless Steel Seamless Pipe/Tube | Wall Thickness: | 0.5mm - 60mm |

Type 316Ti (UNS S31635) is a titanium stabilized version of Type 316 molybdenum - bearing austenitic stainless steel.

316Ti (UNS S31635) is a titanium stabilised version of 316 molybdenum - bearing austenitic stainless steel. The 316 alloys are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium - nickel austenitic stainless steels such as 304. They also offer higher creep, stress - rupture and tensile strength at elevated temperature. High carbon Alloy 316 stainless steel can be susceptible to sensitisation, the formation of grain boundary chromium carbides at temperatures between approximately 900 and 1500° F (425 to 815° C) which can result in intergranular corrosion. Resistance to sensitisation is achieved in Alloy 316Ti with titanium additions to stabilise the structure against chromium carbide precipitation, which is the source of sensitisation. This stabilisation is achieved by an intermediate temperature heat treatment, during which the titanium reacts with carbon to form titanium carbides. This significantly reduces susceptibility to sensitisation in service by limiting the formation of chromium carbides. Thus, the alloy can be used for extended periods at elevated temperatures without compromising its corrosion resistance. 316Ti has equvilent corrosion resistance to sensitisation as the low carbon version 316L.

Processing

The possibilities for cold forming 316Ti are very good. The considerably greater strain hardening compared to plain steel grades demands correspondingly higher forming forces. The annealing colours or scaling occurring during hot forming or welding impair the corrosion resistance. They must be removed by pickling, grinding or sand - blasting (iron free). Metal - cutting machining must be performed with tools made of high - quality high - speed steel (good cooling necessary), or preferably with carbide tools, owing to the strain hardening and the low thermal conductivity. The 316Ti material version displays better cutting properties owing to the specific addition of sulphur.

Welding

Good weldability using all process (except gas welding).

Notes on use

Owing to the addition of titanium as a carbode former, 316Ti is resistant to intercrystalline corrosion, regardless of thickness and cross - section and even when welded, in continuous operation at up to 400 o C. Owing to the molybdenum content, 316Ti displays good resistance to media containing chloride and to non - oxidising acids. 316Ti is used in the construction of apparatus for the chemical and pharmaceutical industries, and for textile finishing.

APPLICATIONS FIELD :

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

If any inquiry about products, please feel free to contact us [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.