Quick Details

- Material: Hastelloy C276 (UNS N10276)

- Technics: Cold forming

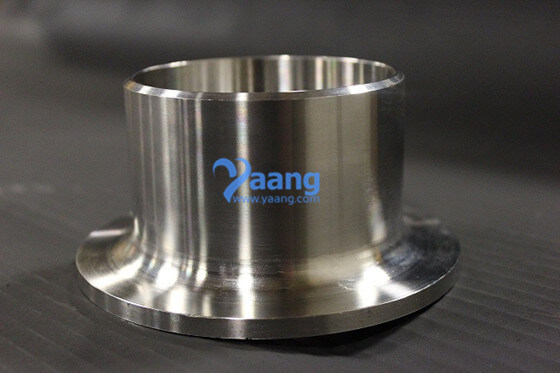

- Type: Hastelloy C276 Stub End

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Connection: Welding

- Shape: Equal

- Head Code: Round

- Standard: ANSI B16.9, ASTM, etc

- Size: 1/2" To 48" (DN15-1200)

Packaging & Delivery

| Packaging Details: | Plywood case or fumigated woodern case or as per customers' requests. |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

ASTM B366 UNS N10276 Hastelloy C276 Stub End

1.Size: 1/2" To 48" (DN15-1200)

2.WT: Sch5-Sch160,XS,XXS,STD

3.Material: Hastelloy C276 (UNS N10276), etc

4.Standard: ASME, JIS, DIN, ANSI, etc.

UNS N10276 Hastelloy C276 is very useful materials for the manufacture of high quality tubing products. One of the key reasons is that they offer excellent corrosion resistance in both aqueous and high temperature applications.

Specifications - ASTM B366 UNS N10276 Hastelloy C276 Stub End

ASTM

B619, B366, B564

ASME

SB619, SB366, SB564

2.WT: Sch5-Sch160,XS,XXS,STD

3.Material: Hastelloy C276 (UNS N10276), etc

4.Standard: ASME, JIS, DIN, ANSI, etc.

UNS N10276 Hastelloy C276 is very useful materials for the manufacture of high quality tubing products. One of the key reasons is that they offer excellent corrosion resistance in both aqueous and high temperature applications.

Specifications - ASTM B366 UNS N10276 Hastelloy C276 Stub End

| ASTM | B619, B366, B564 |

| ASME | SB619, SB366, SB564 |

Chemical Composition - ASTM B366 UNS N10276 Hastelloy C276 Stub End

C

Co

Cr

Fe

Mn

Mo

Ni

P

S

Si

V

W

Max

Max

Max

Max

Max

Max

Max

0.01%

2.5%

14.5%

-16.5%

4-7%

1.0%

15 -17%

BAL

.04%

0.03%

0.08%

0.35%

3-4.5%

Mechanical & Physical Properties Of ASTM B366 UNS N10276 Hastelloy C276 Stub End

Chemical Composition - ASTM B366 UNS N10276 Hastelloy C276 Stub End

| C | Co | Cr | Fe | Mn | Mo | Ni | P | S | Si | V | W |

| Max | Max | Max | Max | Max | Max | Max | |||||

| 0.01% | 2.5% | 14.5% -16.5% |

4-7% | 1.0% | 15 -17% | BAL | .04% | 0.03% | 0.08% | 0.35% | 3-4.5% |

Mechanical & Physical Properties Of ASTM B366 UNS N10276 Hastelloy C276 Stub End

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

What are the characteristics of Hastelloy C276?

1、Excellent corrosion resistance in reducing environments

2、Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

3、High nickel and molybdenum contents providing good corrosion resistance in reducing environments

4、Low carbon content which minimizes grain-boundary carbide precipitation during welding to in heat-affected zones of welded joints

5、Resistance to localized corrosion such as pitting and stress-corrosion cracking

6、One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Design Features - UNS N10276 Hastelloy C276

1、Outstanding corrosion resistance and oxidizing environments.

2、Excellent resistance to pitting and stress-corrosion cracking.

3、Maintains corrosion resistance in welded joints.

Application of ASTM B366 UNS N10276 Hastelloy C276 Stub End

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

5. Oil and Gas Pipeline industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

Stub Ends

What are they?

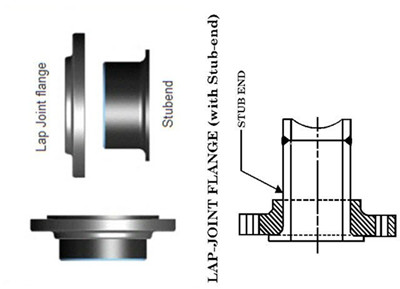

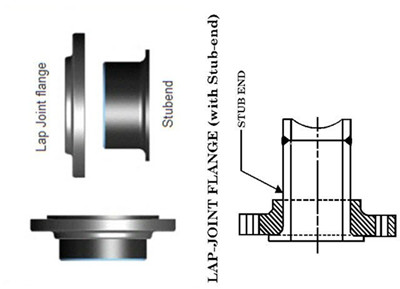

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

Stub Ends' Types

Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

Stub Ends are available in two standard lengths, MSS and ANSI.

Stub Ends are normally provided with a standard weld bevel

Stub End dimensions are found on our fitting dimensions page.

Type "A" - Type "B" - Type "C" - Type "CS"

Where can we find the high quality ASTM B366 UNS N10276 Hastelloy C276 Stub End.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

What are the characteristics of Hastelloy C276?

1、Excellent corrosion resistance in reducing environments

2、Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

3、High nickel and molybdenum contents providing good corrosion resistance in reducing environments

4、Low carbon content which minimizes grain-boundary carbide precipitation during welding to in heat-affected zones of welded joints

5、Resistance to localized corrosion such as pitting and stress-corrosion cracking

6、One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Design Features - UNS N10276 Hastelloy C276

1、Outstanding corrosion resistance and oxidizing environments.

2、Excellent resistance to pitting and stress-corrosion cracking.

3、Maintains corrosion resistance in welded joints.

Application of ASTM B366 UNS N10276 Hastelloy C276 Stub End

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

5. Oil and Gas Pipeline industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

Stub Ends

What are they?

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

Stub Ends' Types

Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

Stub Ends are available in two standard lengths, MSS and ANSI.

Stub Ends are normally provided with a standard weld bevel

Stub End dimensions are found on our fitting dimensions page.

Type "A" - Type "B" - Type "C" - Type "CS"

Where can we find the high quality ASTM B366 UNS N10276 Hastelloy C276 Stub End.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]