- SITEMAP

- CONTACT US

- 8618267732328

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

DIN 17456, DIN 17458 317L Stainless Steel Seamless Pipe With Different Thickness

- FOB PriceUSD 800 - 30,000/Piece

- PortNingbo or Shanghai

- MOQ0.5 Tons

- Supply Ability1000 Tons Per Month

- Payment TermsL/C,T/T,Western Union

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 15 days

Quick Detail:

Name: DIN 17456 , DIN 17458 317L Stainless Steel Seamless Pipe With Different Thickness

Place of Origin:Zhejiang, China (Mainland) Brand Name: Yaang

Shape: Seamless Stainless Steel Pipe Material: stainless steel

Steel Grade: 317L ...

Packaging & Delivery

| Packaging Detail: | according to customer's require or export's standard |

| Delivery Detail: | 2 - 15 days after confirmation |

Specifications:

317L Stainless Steel Pipes and Tubes

317L Stainless Steel Pipes and Tubes Specifications: ASTM A/ASME SA 312/269/213/358 317L Stainless Steel Pipes and Tubes

Sizes (Seamless): 1/2" NB - 8" NB

317L Stainless Steel Pipes and Tubes Sizes (ERW): 1/2" NB - 24" NB

317L Stainless Steel Pipes and Tubes Sizes (EFW): 6" NB - 100" NB

317L Stainless Steel Pipes and Tubes Wall Thickness available:

Schedule 5S - Schedule XXS (heavier on request)

Alloy 317L (UNS S31703) is a molybdenum - bearing austenitic stainless steel with greatly increased resistance to chemical attack as compared to the conventional chromium - nickel austenitic stainless steels such as Alloy 304. In addition, Alloy 317L offers higher creep, stress - to - rupture, and tensile strength at elevated temperatures than conventional stainless steels. It is a low carbon or "L" grade which provides resistance to sensitization during

welding and other thermal processes

317L Stainless Steel Pipes and Tubes Dimensions:

All Pipes is manufactured and inspected/tested to the relevant standards including ASTM, ASME and API etc.

General Properties

Alloy 317LMN and 317L are molybdenum - bearing austenitic stainless steels with greatly increased resistance to chemical attack as compared to the conventional chromium - nickel austenitic stainless steels such as Alloy 304. In addition, 317LMN and 317L alloys offer higher creep, stress - to - rupture, and tensile strengths at elevated temperatures than conventional stainless steels. All are low carbon or "L" grades to provide resistance to sensitization during welding and other thermal processes. The "M" and "N" designations indicate that the compositions contain increased levels of molybdenum and nitrogen respectively. The combination of molybdenum and nitrogen is particularly effective in enhancing resistance to pitting and crevice corrosion, especially in process streams containing acids, chlorides, and sulfur compounds at elevated temperatures. Nitrogen also serves to increase the strength of these alloys. Both alloys are intended for severe service conditions such as flue gas desulfurization (FGD) systems.

MAIN PRODUCTION STANDARDS:

|

STANDARD TYPE |

STANDARD |

|

EN |

EN10216 - 5, EN10216 - 2 |

|

DIN |

DIN 17456, DIN 17458 |

|

ASTM |

ASTM A312, A213, A269, A511, A789, A790 ETC |

|

GOST |

GOST 9941, GOST 5632 |

|

JIS |

JIS G3459, JIS G3463 |

|

GB |

GB/T14975, GB/T14975, GB13296, GB5310, GB9948 |

Stainless Steel Seamless Pipe:

1.A999/A999M: Each pipe shall be subjected to the nondestructive electric test or the hydrostatic test, the pipe of test to be used shall be at the option of the mfg, unless otherwise specified in the PO.

2. The Pipe lengths: Unless otherwise agreed upon, all size from NPS 1/8” TO AND INCLUDING nps 8 are available in a length up to 24ft with the permitted range of 15 to 24 ft. Short length are acceptable and the number and min, length shall be agreed upon between mfg and purchaser.

3. The finished pipe shall be reasonably straight and shall have workmanlike finish, Removal of imperfections by grinding is permitted, provided the W.T are not decreased to the less than the permitted in Section 9 of Specification A999/A999M

4. Butt Weld End: According to ANSI B 16.25

5. Pipe Marking: Specified in A999/999M, include “ Logo+Standard+SIZE+Heat No.+Lot No.+H.T/E.T/U.T”

6. Packing: Each Pipe end is protected by Plastic cap. Then packed by Anti - rust steel strip, The outside of the bundle is plastic woven bag, or Plastic film.

7. Packing Mark: SIZE + STEEL GRADE+ QTY OF PIECE/WEIGHT/METRE.

Standard Specification:

ASTM A213/A213M - 11a: Standard Specification for Seamless Ferritic and Austenitic Alloy - Steel Boiler, Superheater, and Heat - Exchanger Tubes

ASTM A269 - 10: Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A312/A312M - 12: Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A511/A511M - 12: Standard Specification for Seamless Stainless Steel Mechanical Tubing

ASTM A789/A789M - 10a: Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

ASTM A790/A790M - 11: Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

DIN 17456 - 2010: GENERAL PUROSE SEAMLESS CIRCULAR STAINLESS STEEL TUBES.

DIN 17458 - 2010: Seamless Circular of Austenitic Stainless Steel Tube

EN10216 - 5 CT 1/2: Stainless Steel Seamless Pipe & Tube

GOST 9941 - 81: SEAMLESS COLD - AND WARM - WORKED TUBES MADE OF CORROSION RESISTANT STEEL.

Others like BS, JIS standard or can supply

Description:

|

Mechanical Property |

Material Item |

304 |

304L |

304 |

316L |

Top Technology |

|

Tensile Strength |

≥ 520 |

≥ 485 |

≥ 520 |

≥ 485 |

||

|

Yield Strength |

≥ 205 |

≥ 170 |

≥ 205 |

≥ 170 |

||

|

Extension |

≥ 35% |

≥ 35% |

≥ 35% |

≥ 35% |

||

|

Hardness (HV) |

< 90 |

< 90 |

< 90 |

< 90 |

APPLICATIONS FIELD :

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

If any inquiry about products, please feel free to contact us [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

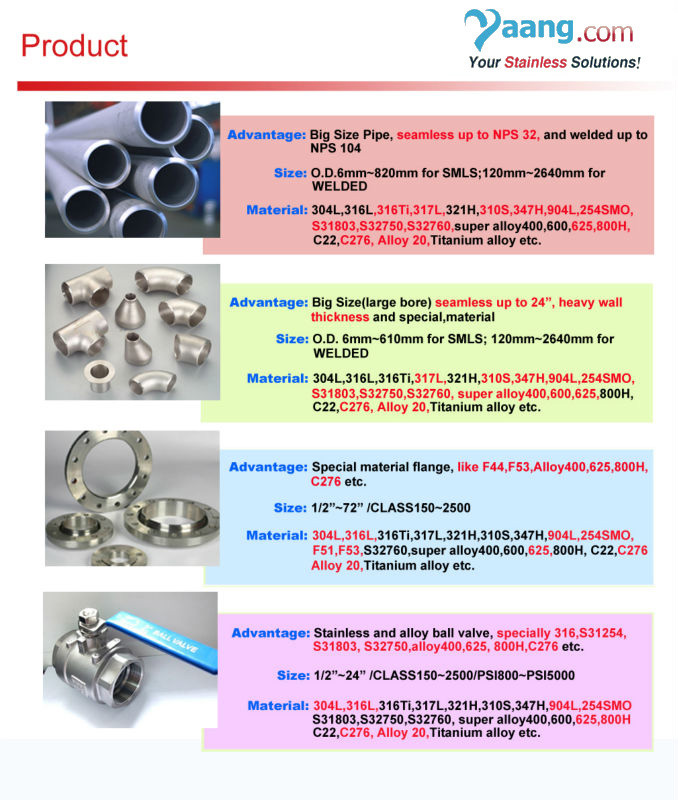

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.