Quick Details

| Material: |

Alloy 625, etc

|

Technics: |

Forged

|

Type: |

Alloy 625 Support Ring

|

| Place of Origin: |

Zhejiang, China (Mainland)

|

Head Code: |

Round

|

Brand Name: |

|

| Connection: |

Welding

|

Shape: |

Equal

|

|

|

Packaging & Delivery

| Packaging Details: |

plywood case or fumigation woodern case |

|---|

| Delivery Detail: |

2 - 10 days |

|---|

Specifications

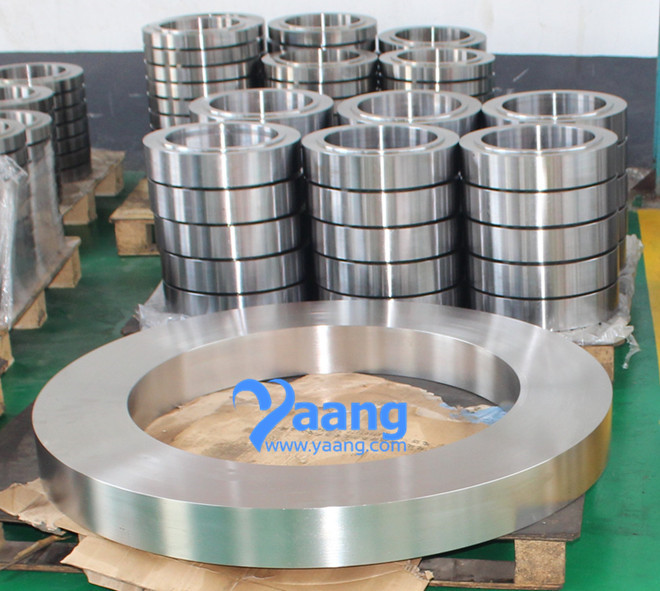

Alloy 625 Support Ring

1. Dimension:

outer Diameter

|

350mm~5000mm

|

Inner Diameter

|

100mm~4800mm

|

Height

|

45mm~650mm

|

Weight

|

200kg~6000kg

|

The Alloy 625 Support Ring is in a semicircular structure, and is characterized in that: a blank structure of the support ring is a wide and flat wire structure. Description Of Alloy 625 Support Ring

Type

|

Alloy 625 Support Ring |

Size

|

OD:384mm×ID:322mm Thk:20mm

|

Standards

|

ASME, ASTM, DIN, JIS, etc

|

Material

|

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

|

Haet treatment

|

Normalized / Annealed / Quenched / tempered

|

Applications

|

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

|

| UNS |

N06625 |

| Werkstoff Nr. |

2.4856 |

What are the characteristics of Inconel 625?

- High creep-rupture strength

- Oxidation resistant to 1800° F

- Seawater pitting and crevice corrosion resistant

- Immune to chloride ion stress corrosion cracking

- Non-magnetic

Chemical Composition, % Of Alloy 625 Support Ring

| Cr |

Ni |

Mo |

Co + Nb |

Ta |

Al |

Ti |

C |

|---|

| 20.00-30.00 |

Remainder |

8.0-10.0 |

1.0 max |

3.15-4.15 |

.40 max |

.40 max |

.10 max |

| Fe |

Mn |

Si |

P |

S |

|

|

|

|---|

| 5.0 max |

.50 max |

.50 max |

.015 max |

.015 max |

Mechanical & Physical Properties – Inconel 625

| Density |

8.4 g/cm3 |

| Melting Point |

1350 °C (2460 °F) |

| Tensile Strength |

Psi – 135,000 , MPa – 930 |

| Yield Strength (0.2%Offset) |

Psi – 75,000 , MPa – 517 |

| Elongation |

42.5 % |

In what applications is Inconel 625 used?

- Aircraft ducting systems

- Aerospace

- Jet engine exhaust systems

- Engine thrust-reverser systems

- Specialized seawater equipment

- Chemical process equipment

Inconel 625 is a corrosion and oxidation resistant nickel alloy that is used both for its high strength and outstanding aqueous corrosion resistance. Inconel Alloy 625 has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is frequently used to weld AL-6XN.

Alloy 625 Support Ring Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps,

pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality Alloy 625 Support Ring.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us [email protected]