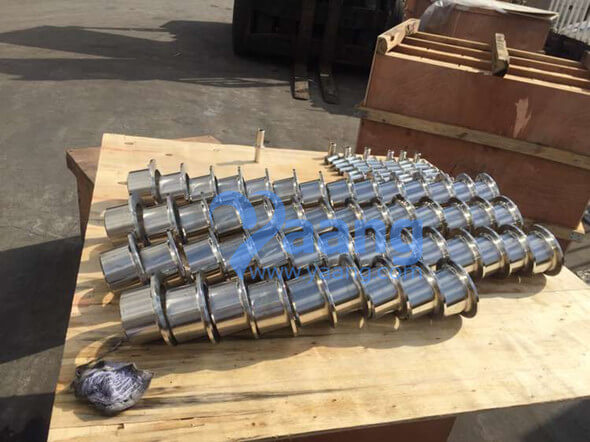

Packaging & Delivery

| Packaging Details: | fumigation free plywood cases or as per customers' requests |

|---|---|

| Delivery Detail: | 2 - 15 Days Delivery after receiving deposit |

PRODUCTS

Credibility ,

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

| Packaging Details: | fumigation free plywood cases or as per customers' requests |

|---|---|

| Delivery Detail: | 2 - 15 Days Delivery after receiving deposit |

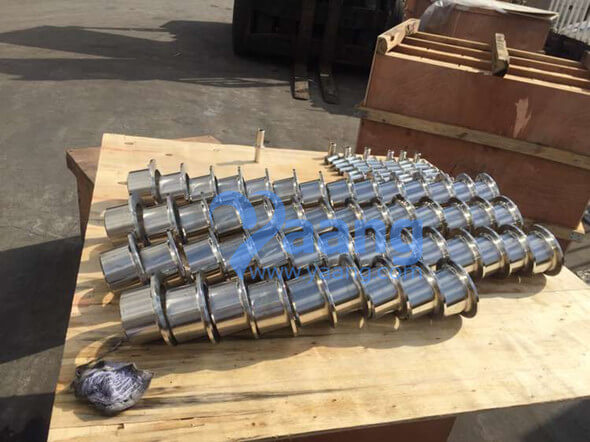

ASTM A403 MSS SP-43 WP316 Stub End DN100 SCH40S

1.Material: 316L Stainless Steel

2.Pressure: 150#, 300#, 600#, etc.

3.Size: 4"

| ASTM A403 MSS SP-43 WP316 Stub End DN100 SCH40S | ||

| 1 | Type: | Stub End |

| 2 | Size: | 1/2" - 60" |

| 3 | Wall thickness: | Sch5S-Sch160, XS, XXS(1.2mm~34mm) |

| 4 | Standard: | GB, JIS, BS, DIN, ANSI, etc |

| 5 | Material: | Stainless Steel: ASTM A403 WP304, 304L, 310, 316, 316L, 321, 347, 904L Super & Duplex Stainless Steel: UNS 31803, UNS 32750 ,UNS 32760, etc. Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51, etc Super Duplex Stainless Steel: S32750/2507/F53/F55, UNS32760, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc |

| 6 | Pressure ratings: | PN: 6, 10, 16, 25, 40, 64 and 160, 5K-40K and so on |

| 7 | Sealing surface: | Sand Rolling, Sand Blasting, Acid Cleaning. |

| 8 | Marking: | according to client's requirement. |

| 9 | Application: | petroleum, chemical, power, gas, water, linepipe, heat exchanger, shipbuilding, construction, etc. |

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes and pipe fittings with special specifications according to customers’ requirements.

Stub Ends

What are they?

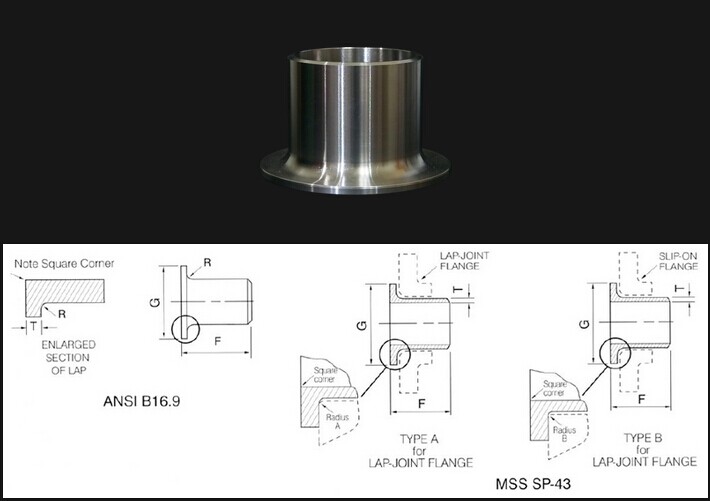

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

Stub Ends' Types

Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

Stub Ends are available in two standard lengths, MSS and ANSI.

Stub Ends are normally provided with a standard weld bevel

Stub End dimensions are found on our fitting dimensions page.

Type "A" - Type "B" - Type "C" - Type "CS"

Where can we find the high quality ASTM A403 MSS SP-43 WP316 Stub End DN100 SCH40S.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.