Ξ

- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

PRODUCT SERIES

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Your Location: Home > News

News - Yaang

Barriers to the use of duplex stainless steel

DataTime:[2018-9-20]

The attractive combination of high strength, extensive corrosion resistance and moderate weldability seems to provide great potential for increasing the market share of duplex stainless steel. However, it is necessary to understand the limitations before using duplex stainless steel.

The advantages of high strength can also be a drawback when considering formability and workability. High strength will have a lower ductility than the austenite grade. Therefore, exclude any double grade applications that require high formability, such as flume. Even if the ductility is enough, a higher force is needed to form materials, such as tube bending. An exception to the normal rule of poor machinability is 1.4162.

Metallurgy of duplex stainless steel is much more complicated than austenitic or ferritic steel. This factor means that they are more difficult to produce and manufacture in mills.

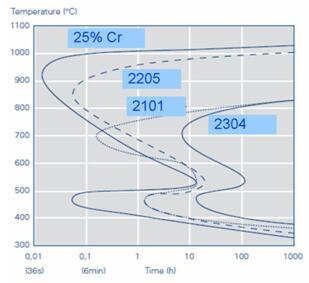

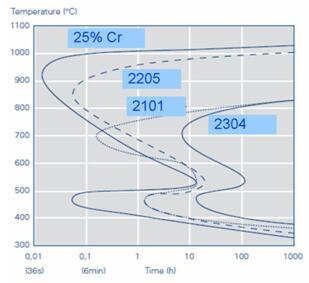

In addition to ferrite and austenite, if the steel is not properly processed, especially in heat treatment, the duplex stainless steel can form many non - needed phases. The two most important stages are shown in the following figure:

These two stages will lead to embrittlement, that is, the loss of impact toughness.

When the cooling rate in manufacturing or welding is not fast enough, the formation of the sigma phase is most likely. The higher the alloying of the steel, the higher the probability of the formation of the sigma phase. Therefore, it is the most likely problem for duplex stainless steel.

The embrittlement of 475 degrees Celsius is due to the formation of a phase called alpha (alpha). Although the worst temperature is 475 degrees Celsius, it can still be formed at temperatures as low as 300 degrees Celsius. This leads to the maximum temperature limit of dual phase steel. This limitation further reduces the potential range of application of the material.

At the other end of the scale, the low temperature usage of duplex stainless steel is limited compared with austenitic stainless steel. The ductile brittle transition of austenitic stainless steel duplex stainless steel in impact test is shown. The typical test temperature for offshore oil and gas applications is 46 degrees below zero. A temperature reduction of 80 degrees Celsius is the lowest temperature commonly encountered in duplex stainless steel.

Source: China Duplex Stainless Steel Pipe Fittings Manufacturer - Yaang Pipe Industry Co., Limited (www.yaang.com)

The advantages of high strength can also be a drawback when considering formability and workability. High strength will have a lower ductility than the austenite grade. Therefore, exclude any double grade applications that require high formability, such as flume. Even if the ductility is enough, a higher force is needed to form materials, such as tube bending. An exception to the normal rule of poor machinability is 1.4162.

Metallurgy of duplex stainless steel is much more complicated than austenitic or ferritic steel. This factor means that they are more difficult to produce and manufacture in mills.

In addition to ferrite and austenite, if the steel is not properly processed, especially in heat treatment, the duplex stainless steel can form many non - needed phases. The two most important stages are shown in the following figure:

These two stages will lead to embrittlement, that is, the loss of impact toughness.

When the cooling rate in manufacturing or welding is not fast enough, the formation of the sigma phase is most likely. The higher the alloying of the steel, the higher the probability of the formation of the sigma phase. Therefore, it is the most likely problem for duplex stainless steel.

The embrittlement of 475 degrees Celsius is due to the formation of a phase called alpha (alpha). Although the worst temperature is 475 degrees Celsius, it can still be formed at temperatures as low as 300 degrees Celsius. This leads to the maximum temperature limit of dual phase steel. This limitation further reduces the potential range of application of the material.

At the other end of the scale, the low temperature usage of duplex stainless steel is limited compared with austenitic stainless steel. The ductile brittle transition of austenitic stainless steel duplex stainless steel in impact test is shown. The typical test temperature for offshore oil and gas applications is 46 degrees below zero. A temperature reduction of 80 degrees Celsius is the lowest temperature commonly encountered in duplex stainless steel.

Source: China Duplex Stainless Steel Pipe Fittings Manufacturer - Yaang Pipe Industry Co., Limited (www.yaang.com)

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.