- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Effect of forging process on microstructure and properties of 2219 aluminum alloy flange

In order to solve the problems of 2219 aluminum alloy flange forgings, such as coarse grain, vertical fiber direction and structural stress direction, the effect of forging process on its structure and properties was studied by means of room temperature tensile test and optical microscope. The results show that the single upsetting process has little effect on the structure and properties; The multi-directional forging process can effectively break the fiber structure of the bar and reduce the anisotropy of the forging. For all kinds of forging processes formed at one time under high temperature, the grain size of forgings reaches millimeter level; When the deformation is finished at a lower final forging temperature, the microstructure of the forging can be significantly refined and homogenized; The 2219 aluminum alloy flange forgings with uniform structure and fine grain can be obtained by using the two upsetting and one drawing deformation process with lower final forging temperature, and the radial elongation of the forgings is 57% higher than the axial elongation, which significantly improves the reliability of the welding structure.

0. Introduction

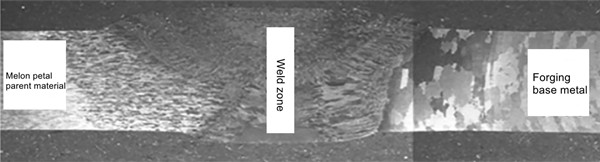

There were two quality problems in the manufacturing process of a new type of launch vehicle. One was the cracking at the weld of the manhole cover flange during the air-tight inspection of the secondary hydrogen tank; Second, after the oxygen delivery flange of the primary oxygen tank is welded, there are linear defects on the side of the weld near the flange forging during the X-ray inspection. See Fig.1 for the metallographic structure of the weld zone. The welded flange structure at the bottom of the tank is formed by butt welding of melon flap and flange or by butt welding of flanges of different specifications. The melon flap is formed by creep aging of 2219 aluminum alloy plate, and the flange is forged from 2219 aluminum alloy bar and then machined. At present, the welded flange structure has such problems as unequal strength on both sides of the welded joint, large difference in structure, coarse grain on the side of the flange forging and the fiber direction perpendicular to the stress direction of the structure, so it is easy to fracture on the side of the flange forging when under pressure. Even if both sides of the butt weld are flange forgings, the performance fluctuation and structure difference are often large due to different specifications, which affects the stability of the welded structure. In order to solve the problems of the 2219 aluminum alloy flange forgings used for welding, such as coarse grain size, vertical fiber direction and structural stress direction, this paper carries out a research on the 2219 aluminum alloy extruded bar forging process, and explores the influence of different forging processes on the structure and properties of the flange, so as to improve the reliability of the welding structure, with a view to improving the overall bearing level of the rocket tank.

1. Test materials and methods

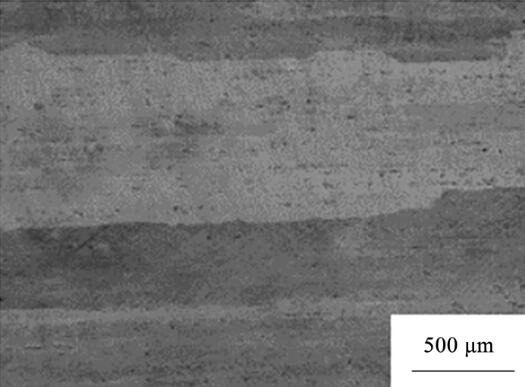

The test raw material is 2219 aluminum alloy bar, with the specification of Φ 150mm × 245mm, the metallographic structure of forgings after T852 heat treatment is shown in Figure 2, and the mechanical properties are shown in Table 1. Rm is the tensile strength, Rp0.2 is the yield strength, and A is the elongation. The fiber direction of the raw material is axial, and the grain is long and large, and the size in the length direction is far more than 2000 μm. The mechanical properties of the raw material in the axial direction are better than that in the radial direction. The strength index is slightly higher, and the elongation A is nearly twice higher.

Table.1 Mechanical properties of 2219 aluminum alloy bar

| Parameter | Axial | Radial | ||||

| Rm/MPa | Rp0.2/MPa | A/% | Rm/MPa | Rp0.2/MPa | A/% | |

| Value | 434 | 322 | 11 | 422 | 317 | 6 |

Table.2 Forging process

| Process No | Deformation process | Final forging temperature/℃ | Deformation direction | Forging ratio |

| 1 | Single upsetting | 442 | Axial | 2.3 |

| 2 | Single upsetting - squaring | 438 | Axial | 3.2 |

| 3 | Two upsetting and one drawing: upsetting-drawing-heading | 435 | Axial | 8.3 |

| 4 | Two upsetting and one drawing: upsetting-drawing-air cooling-upsetting | 380 | Axial | 8.3 |

| 5 | Two upsetting and one drawing: upsetting-drawing-air cooling-upsetting | 300 | Axial | 8.3 |

| 6 | Four upsetting and three drawing: upsetting-drawing - upsetting-drawing - upsetting-drawing - upsetting | 428 | Three-way | 19.2 |

2. Test results and analysis

2.1 Effect of deformation mode and deformation amount on microstructure

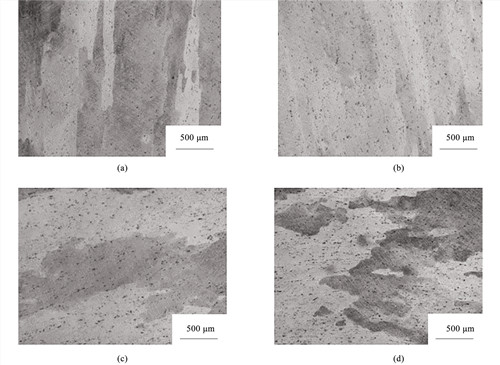

Fig.3c shows the heat-treated structure of the forging after two upsetting and one drawing along the bar axis. It is found that the directivity of the structure is weakened and the grain presents irregular shape, but the grain size is large and the length direction is greater than 1500 μ m. Width direction is 500 μm. Fig.3d shows the heat-treated structure of the forging after the bar is deformed by four upsetting and three drawing. The deformation amount is greatly increased by one upsetting deformation in three directions perpendicular to each other. The forging structure has no fiber direction and the grain size is about 800-1000 μm. The forging process of two upsetting and one drawing and four upsetting and three drawing can change the fiber direction and grain shape and size of the bar to a certain extent. Compared with the single upsetting deformation, although the deformation temperature is 460 ℃, the deformation amount of the former is significantly increased. Through deformation, the material flows, thus changing the fiber structure of the material and changing the grain shape. Although the deformation amount of four upsetting and three drawing is large, it is still a deformed structure rather than a recrystallized structure, which means that although large deformation produces more distortion energy, the softening mechanism at high temperature is still dynamic recovery, and the distortion energy is not enough to make the alloy undergo static recrystallization in the subsequent heat treatment process to refine the grain, so the grain size is still close to millimeter level.

2.2 Effect of final forging temperature on microstructure

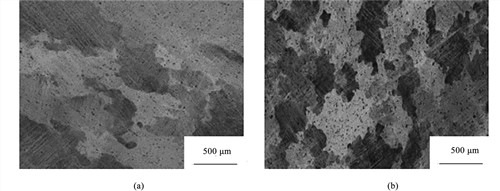

At different final forging temperatures, the microstructure of forgings in T852 state is shown in Figure 4. The initial forging temperature is 460 ℃, and two upsetting and one drawing are used for deformation. Only the final forging temperature is different. According to Fig.3c, its corresponding intermediate cooling is 0 min (one-time forming), and the final forging temperature is the highest. It can be seen that the structure still has certain directionality, and the grain size is the largest, and the length direction size is greater than 1500 μ m. About 500 in width direction μm. Fig.4a corresponds to the intermediate cooling for 5min, followed by the final forging temperature, the structure has no fiber direction, and the grain size becomes smaller, about 500-800 μm. Fig.4b corresponds to the intermediate cooling for 15min, the final forging temperature is the lowest, the structure has no fiber direction, and it is a relatively uniform recrystallized structure, and the grain size is about 300-400 μm.

2.3 Effect of deformation mode and deformation amount on mechanical properties

Table.3 Mechanical properties of forgings under different forging processes

| Process No | Axial | Radial | ||||

| Rm/MPa | Rp0.2/MPa | A/% | Rm/MPa | Rp0.2/MPa | A/% | |

| 1 | 406 | 304 | 10 | 419 | 321 | 6 |

| 2 | 425 | 316 | 9.5 | 428 | 320 | 7.3 |

| 3 | 408 | 300 | 8.3 | 425 | 324 | 7.5 |

| 6 | 423 | 316 | 9.5 | 424 | 312 | 10 |

2.4 Effect of final forging temperature on mechanical properties

Table.4 Mechanical properties of forgings under different final forging temperatures

| Process No | Axial | Radial | ||||

| Rm/MPa | Rp0.2/MPa | A/% | Rm/MPa | Rp0.2/MPa | A/% | |

| 3 | 408 | 300 | 8.3 | 425 | 324 | 7.5 |

| 4 | 418 | 312 | 7.5 | 420 | 316 | 9.8 |

| 5 | 417 | 313 | 7 | 417 | 301 | 11 |

3. Conclusion

- (1) The bar has obvious axial fiber structure. The forging process of single upsetting cannot change the fiber structure direction, grain size and morphology, and has little effect on the structure and properties of the forging.

- (2) The forging process of two upsetting and one drawing, four upsetting and three drawing can effectively weaken the directionality of the bar structure and make the isotropic properties of the forgings equal; The four-upsetting and three-drawing process has greater deformation, more sufficient deformation in all directions, and the corresponding forging structure is more uniform, but the grain size is still close to millimeter.

- (3) The forging process is hollow and cold for a certain time. By reducing the final forging temperature, the grain size and uniform structure can be significantly refined.

- (4) The 2219 aluminum alloy flange forgings with uniform structure and fine grain can be obtained by using the two upsetting and one drawing deformation process with lower final forging temperature. The radial elongation is 57% higher than the axial elongation, which can significantly improve the reliability of the welding structure.

Source: China Aluminum Alloy Flange Manufacturer - Yaang Pipe Industry Co., Limited (www.yaang.com)

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.