- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Installation position of check valve

Let's discuss the installation position of the check valve today. So how to determine the installation position of check valve? What is the difference between the installation before the pump and the check valve after the pump, and where is the pre pump installation applicable? Check valve is usually used with other valves. Where should check valve be installed when used with other valves? Let's discuss it together.

Check valve is an automatic valve. It relies on the pressure of the flowing medium in the pipeline to push the valve disc to close and open the valve. When the medium stops flowing, the check valve disc will close. It can effectively prevent the medium in the pipeline from backflow, which plays a great role in ensuring the safety of the pipeline.

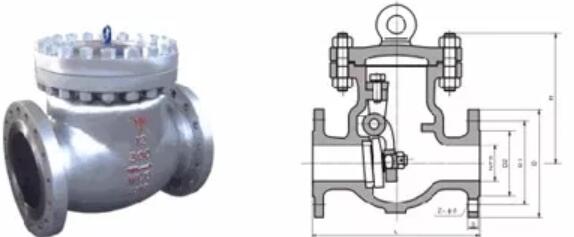

According to the structure, check valve can be divided into lift check valve, swing check valve and butterfly check valve. Lift check valve can be divided into vertical and straight through type. Swing check valve is divided into three types: single valve, double valve and multi valve. Butterfly check valve is divided into butterfly double valve and butterfly single valve. The above check valves can be divided into threaded connection, flange connection, welding and clamp connection.

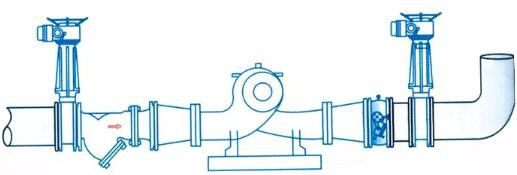

The installation of check valve is to ensure the flow direction of water inside the pump, so as to ensure the normal operation of the pump. Therefore, the installation position of the check valve can be divided into two situations: before the water pump or after the water pump

One is installed at the end of the vertical suction pipe in front of the water pump, also known as the bottom valve. The purpose is not to pump a water to the pump to fill a water, because the pump and the pump in front of the suction pipe when there is no water, the pump can only idle pumping water, so the pump must be filled with water to pump water. The installation of this pump is a method higher than the liquid level, also known as negative pressure method.

The other is installed behind the pump. This installation method is that when the liquid level is higher than the water pump, it is convenient to shut down the water outlet valve of the pump when starting and stopping the water pump, especially for the main control water pump system to prevent the backflow.

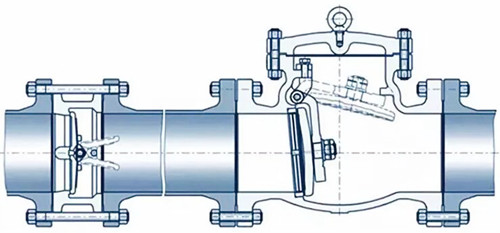

The check valve must be installed at the outlet of the pump and in front of the outlet control valve to facilitate the maintenance of the check valve. Generally, the first outlet of the pump is the soft connection (shock absorber), followed by the check valve, and then the block valve (such as butterfly valve, gate valve, stop valve, etc.).

1. First install check valve, then install gate valve or butterfly valve

Advantages: it can protect the check valve, especially in the parallel pump. When one pump is not started, its outlet valve is closed, and the other pump is started, the impact force is borne by the gate valve or butterfly valve. When the check valve fails, the inlet and outlet valve isolation system can be closed for repair.

Disadvantages: who will protect gate valve or butterfly valve? There was a case where the valve plate of butterfly valve was broken.

2. Install gate valve or butterfly valve before check valve

Advantages: it can protect butterfly valve or gate valve, and the impact force is borne by check valve.

Disadvantages: who will protect the check valve? The check valve is opened and closed by the pressure difference. If the main pipe pressure is high, it will be closed and the pump pressure is high, it will be opened. If the flow is unstable, the check valve will be opened and closed repeatedly, which will affect the service life of the check valve. Moreover, the check valve is broken, especially the main control system, which needs to be shut down before repair.

Generally speaking, due to the frequent opening and closing actions of check valves, the internal connection parts and sealing parts are easy to be damaged. In order to facilitate repair and prevent the shutdown of the whole system due to the failure of check valves, from this point of view, check valves will be installed in front of outlet gate valves or butterfly valves. Is that basically what you see?

Source: China Valves Manufacturer – Yaang Pipe Industry Co., Limited (www.yaang.com)

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.