- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

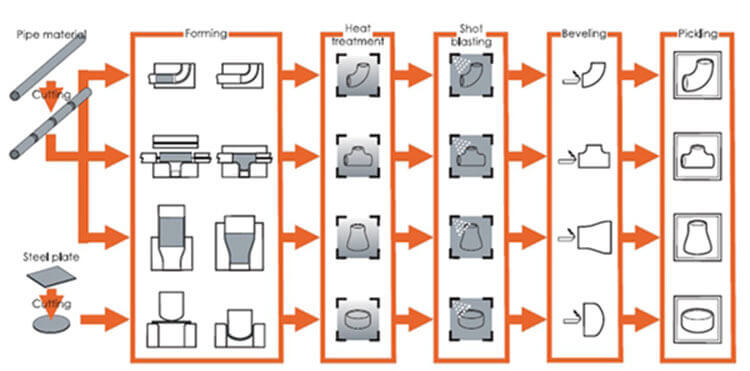

Manufacturing process of stainless steel pipe fittings

Manufacturing process of stainless steel pipe fittings

Blanking

The main materials used for pipe fittings are pipes, plates and bars, and the blanking method is selected according to the material characteristics and the shape of the billets used in the products. The shape, size, and other requirements of the billet are performed in accordance with the process specifications for different products.

The pipe material commonly used under the band sawing machine or bow cutting, gas cutting, plasma cutting machine.

For the plate material, commonly used methods are cutting, plasma cutting, punching punch.

For the bar, material commonly used under the band sawing machine sawing machine for cutting, punching and cutting or bow.

Forming (welding)

Forming is an indispensable process for the manufacture of all pipe fittings. Since the forming processes of different products are different and require longer space, they will be described in section 15.2.4. Here, a brief introduction to the heating and welding included in the part forming process is presented.

A.. Heating

In order to meet the requirement of material deformation in forming process, the billet must be heated during the forming process. Heating temperature usually depends on material and process.

Hot bend or hot bending forming, intermediate and high frequency induction heating method is usually adopted, but also the use of flame heating method. The heating method is continuous heating with the forming process of the elbow or the bent pipe, the tube blank is heated in the movement and the forming process is completed.

Hot pressing elbow, hot pressing three pass or forging forming, usually using reverberatory furnace heating method, flame heating method, induction heating method or electric furnace heating method, etc.. This heating is the process of heating the tube to the desired temperature before putting it into the mold and pressing or forging it.

B. welding

Fittings with weld includes two kinds of situations, one is fitting for welded pipe, the pipe manufacturing factory, the welded pipe forming process and forming process of the seamless tube is basically the same, the pipe forming process does not include the welding process; the other is the factory to complete the required weld pipe forming process by fitting. Such as a pressing after elbow, assembly welding with rolling steel plate after welding tube and then pressed into three links etc..

The welding methods of pipe fittings are manual arc welding, gas shielded welding and automatic welding.

The welding procedure shall be worked out by the manufacturer to guide the welding work, and the welding procedure qualification shall be evaluated according to the relevant specifications so as to verify the correctness of the welding procedure regulations and evaluate the welding ability of the welders.

Engaged in pipe welding welder who should pass the quality and Technology Supervision Department of the examination and obtain the corresponding qualification certificate shall be engaged in relevant steel welding work (according to the regulations, some industries for welding fittings in some industries to achieve industry regulations of welders and welding technology evaluation, such as ship pipe welding to obtain the corresponding classification welders and welding process qualification).

Heat treatment

Heat treatment process is an important part of pipe manufacturing. Through the heat treatment step heating, insulation and cooling, eliminate work hardening and forming process of the residual stress and deformation of metal defects, metal fittings, organizational performance change after forming, return to the state before the deformation or the performance can be improved and enhanced.

The commonly used heat treatment equipment is the reverberatory furnace, the electric stove, and so on. The usual control way is the thermocouple in the furnace is connected to the control device of the temperature time automatic recorder by the sensor.

The standards for heat treatment in different pipe fittings are not the same. Not all the fittings are to be deformed after heat treatment, usually for low carbon steel pipe, the final forming temperature not lower than 723 DEG C (recrystallization temperature), without heat treatment, because in the condition of the final state basically is normalizing state, below this temperature or above 980 degrees should undergo heat treatment; alloy steel pipe or stainless steel material whether by cold forming or hot forming, heat treatment shall be carried out.

Routine inspection of heat treatment is done by hardness test.

Surface treatment

The surface pipe fitting usually adopts sand blasting, shot blasting, polishing, pickling and other methods to remove surface rust, scratches etc., make the products reach the smooth surface, meet the subsequent processing and inspection requirements.

The surface hardness of the pipe surface treated by shot blasting will increase slightly.

Cutting process

Cutting is the completion of the end of the pipe welding, structural size, shape and position tolerances processing. For some pipe products, cutting also includes internal, external diameter processing. Cutting through a special machine or tool; for oversized fittings, when existing machine capacity can not meet the processing requirements, can also be processed by other methods, such as method of cutting with large diameter elbow after grinding.

The appearance and size inspection of pipe fittings are usually performed after cutting.

The nondestructive testing

Nondestructive testing is an important procedure to test the defects that may occur during the processing of materials and fittings. The requirements for nondestructive testing are specified in most pipe fittings standards, but the requirements are not the same. In addition to meet the product standard and order requirements for nondestructive testing, some of the more stringent quality control of manufacturing plant according to the materials, processing technology and internal quality control regulations requirements of nondestructive testing, to ensure the quality of manufactured products.

In actual work, the determination of the unqualified grades of pipe fittings shall be made in accordance with the ordering requirements or standards. Because the pipe surface is basically the original pipe, plate or forging state, nondestructive testing on tube surface quality (MT, PT), if there is no clear grade requirements according to grade II, but no matter how qualified grade regulations, defects of the interlayer and the crack is not easy to judge the depth shall be deemed unqualified. For the nondestructive testing of the internal quality of pipe fittings (RT, UT), if there is no definite grade requirement, the radiographic inspection shall be conducted at the level II (e.g., weld detection), and ultrasonic testing shall be of class I.

In order to prevent the possible defects of the product during the heat treatment, the final nondestructive test of the pipe shall be carried out after heat treatment.

The nondestructive testing of pipe fittings factory in our country usually adopts the JB/T 4730 specification. The personnel engaged in nondestructive testing shall obtain the corresponding qualifications in accordance with the relevant provisions.

The surface protection

The surface protection of carbon steel and alloy steel pipes are usually made by coating, and the method of passivation for stainless steel after pickling is adopted. The main purpose of the surface protection of pipe fittings is corrosion protection, and the appearance of the products is also beautiful. In general, the ordering party makes specific requirements for surface protection, and the manufacturer completes the protection of the pipe surface according to the requirements of the ordering party.

The sign

Logo is an integral part of the product, is the basis for achieving traceability requirements. Generally, the contents, methods and regulations are specified in the product standard. The contents of a pipe include the manufacturer's trademark or name, material grade, specifications, and other requirements of the order. Mark method includes permanent marks, such as stamping, carving, electric erosion; non permanent marks, such as printing, label etc..

To the other

In addition to the conventional manufacturing process, to control the quality of raw materials, manufacturers should also complete the inspection of raw materials, to ensure that the material used is correct; in order to satisfy special requirements or ordering materials, should also be such as microstructure, intergranular corrosion, ferrite inspection and testing, to ensure that the the products meet the requirements of customer use.

Source: China Stainless Steel Pipe Fittings Manufacturer - Yaang Pipe Industry Co., Limited (www.yaang.com)

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.