- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Processing Technology of Elliptical Deformation for Machining Sleeve Parts

In the mechanical processing industry, especially the manufacturers of hydraulic components, there are problems such as elliptical deformation and product scrapping when machining sleeve parts. The sleeve type parts have the following characteristics: large diameter, short length, thin wall thickness, high geometric tolerance requirements. Serious elliptical deformation will occur after machining. Therefore, the problem will be solved by properly improving the machining process of sleeve parts according to the above characteristics.

1. The influence of out of tolerance of sleeve parts on the service life of equipment

As a hydraulic component, the supercharged cylinder liner is a kind of sleeve parts. Whether its internal and external surface machining accuracy meets the technical requirements of the drawing is directly related to the operation quality of the entire hydraulic system. The most critical technical requirements are: whether the dimensional tolerance and roundness tolerance of its internal and external surfaces meet the technical requirements. If the tolerance requirements are exceeded: First, the dimension out of tolerance will affect the hydraulic seal and cause hydraulic oil leakage. Second, the elliptical phenomenon on the inner and outer surfaces will affect the service life of the entire hydraulic component. Although it is slightly deformed, no problem can be found in a short time of use: after working for a period of time, due to mechanical wear, the long diameter of elliptical deformed parts will be severely worn down, leakage will occur, and the working pressure of the system will be reduced, so the service life will be significantly shortened. If it is a support sleeve used on the mechanical transmission shaft, it will be elliptical deformation before assembly. Although it can be installed, after a period of use, the long diameter of the elliptical deformation support sleeve will become smaller due to mechanical wear. If it is used again, the fit clearance between the base hole, the support sleeve and the transmission shaft will become larger, which will eventually lead to the base hole becoming larger or the transmission shaft being smaller, or even the base or transmission shaft will be scrapped, This is due to the size of the support sleeve out of tolerance or elliptical deformation. Therefore, it is necessary to ensure that the dimensional tolerance and roundness tolerance of sleeve zero meet the technical requirements of the drawing. The following takes the booster cylinder as an example to explain how to process the process.

2. Technical features of supercharged cylinder liner

During the production and processing of the supercharged cylinder liner, it is often encountered that the workpiece meets the requirements of the drawing during the processing or after the processing and forming. However, when turning to the next process for re processing or the final inspection of the workpiece, serious elliptical deformation occurs. At the beginning, it is judged that the elliptical deformation is related to the cutting amount, cutting speed and clamping method. Therefore, we constantly adjusted the cutting amount, cutting speed and clamping method, but they were not solved in the end. We used external force to knock the workpiece to force it to round, but it did not help. As a result, large quantities of products were scrapped. Even if the small diameter ones were barely qualified, due to the impact of the cutting amount and cutting speed, the working hours and efficiency were affected. Therefore, the economic benefit is low, which can only temporarily meet the needs of customers.

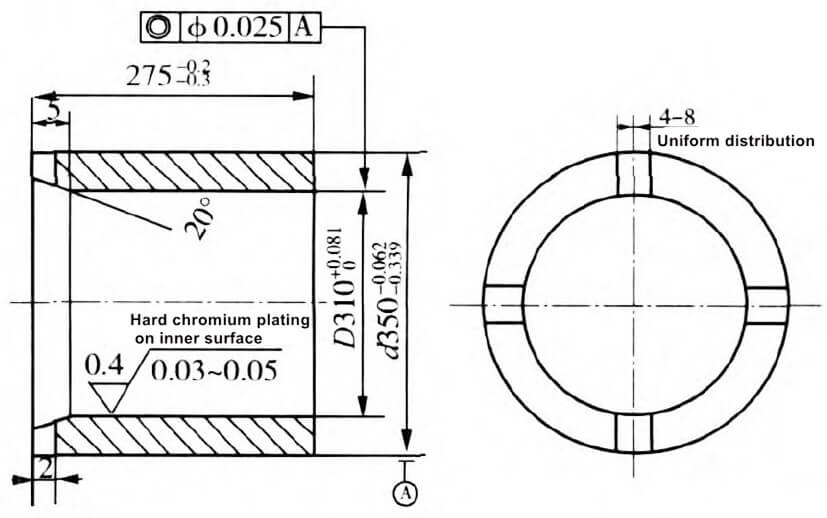

Features of supercharged cylinder liner: generally, the diameter is relatively large, the length is relatively short, the wall thickness is relatively thin, and the form and position tolerance is relatively small. The processing route of this kind of parts is analyzed and studied. For example, the commonly used supercharging cylinder liner on die-casting mechanical equipment is shown in Figure 1.

Fig.1 Booster Cylinder Liner

The general processing route is as follows: blanking (seamless steel pipe) - rough machining (allowance) - quenching and tempering - turning the end face - fine boring the inner hole - honing the inner hole - plating hard chromium on the inner surface - fine turning the outer circle - turning the end face to control the total length - milling the end face groove - inspection and warehousing.

3. Process analysis and improvement

In view of the elliptical deformation phenomenon after the supercharged cylinder liner is processed and formed, the problem has not been effectively solved after improving the fixture, changing the cutting amount, cutting speed and other means. Therefore, we should improve the processing route. According to the characteristics of the supercharged cylinder liner, due to the thin wall and large diameter, the cutting force and heat generated in the cutting process and the internal stress of the material itself cannot be completely released during the processing. After processing and forming, due to the instability of the internal stress and internal organization, after being placed for a period of time, the stress in the parts where the stress is concentrated is released rapidly due to the release of the internal stress, the deformation is large, the internal organization is stable, and the internal stress is dispersed, The stress release is relatively slow, and the relative deformation is smaller. The resulting internal and external surface deformation results in an ellipse, which is the root of the problem. The internal stress of materials is generally removed after semi finishing and between finishing. The effective method of removing internal stress is to take qualitative aging treatment. The specific method of aging qualitative treatment is: the supercharged cylinder liner shall be subject to conditioning treatment first, because the tempering temperature is generally not more than 560 ℃, so the aging qualitative treatment temperature is generally 450 ℃ - 550 ℃ for about 3h, and must not exceed 550 ℃; For small diameter sleeve parts, the internal stress can be removed and the internal metallographic structure tends to be stable after heat preservation and air cooling.

The improved process route is as follows: blanking (seamless steel pipe) - rough machining (allowance) - quenching and tempering treatment - semi finishing - aging qualitative treatment - finishing - honing the inner hole - milling the end groove - inspection and warehousing.

This method is simple in operation and low in cost. Due to the aging treatment of the supercharged cylinder liner, the cutting amount and cutting speed can be carried out according to the normal process, and the working efficiency has been greatly improved. Therefore, the cost of time effective treatment not only has no impact on the economic benefits, but also improves the economic benefits of the enterprise from the perspective of man hour efficiency.

4. Conclusion

Elliptical deformation occurs not only in the processing of hydraulic components' pressurized cylinder liners, but also in the processing and manufacturing of all large diameter, thin wall thickness and short length sleeve parts. Therefore, the improvement of this process can effectively improve the processing accuracy and avoid the occurrence of roundness error. Moreover, the operation method of aging qualitative treatment is simple and the cost is very low. With the addition of aging qualitative treatment process, the processing efficiency has been greatly improved, which effectively solves the elliptical deformation of products, avoids the occurrence of scrap products, and promotes the improvement and development of enterprise economic benefits.

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.