Selection of heat exchanger type and scaling treatment method

1. When the temperature difference is large, floating head heat exchanger, U-shaped tube heat exchanger, stuffing box heat exchanger and sliding tube sheet heat exchanger can be selected. When the shell side is often mechanically cleaned, the structure with withdrawable tube bundle can be selected. Under high temperature and high pressure, U-tube heat exchanger can be selected. When the shell side medium is flammable, explosive, toxic or volatile, and the service pressure and temperature are high, the stuffing box heat exchanger should not be used. When the tube side medium and shell side medium are not allowed to be mixed, the heat exchanger with double tubesheet structure can be used.

2. Types and selection principles of tubular heat exchangers

(1) Tubular heat exchangers can be divided into the following main types:

- ① The tubesheets at both ends of the tube bundle of the tubular heat exchanger are connected with the shell as a whole, with simple structure, but it is only applicable to the heat exchange operation when the temperature difference between cold and hot fluids is small and the shell side does not need mechanical cleaning. When the temperature difference is slightly large and the shell side pressure is not too high, an elastic compensation ring can be installed on the shell to reduce the thermal stress.

- ② The tube sheet at one end of the floating head heat exchanger tube bundle can float freely, which completely eliminates the thermal stress, and the whole tube bundle can be extracted from the shell, which is convenient for mechanical cleaning and maintenance. Floating head heat exchanger is widely used, but its structure is complex and its cost is high.

- ③ Each heat exchange tube of the tubular heat exchanger is bent into a U shape, and both ends are respectively fixed in the upper and lower areas of the same tube plate, which is divided into inlet and outlet chambers with the help of the diaphragm in the tube box. The heat exchanger completely eliminates the thermal stress and has a simpler structure than the floating head sheet type, but the tube side is not easy to clean. For the heat exchange of highly corrosive fluids in chemical production, non-metallic materials such as ceramics, glass, polytetrafluoroethylene and graphite need to be used to make shell and tube heat exchangers. This kind of heat exchanger has poor heat exchange performance and is only used in occasions with low pressure, low vibration and low temperature.

(2) For the cold and hot fluids for heat exchange, the flow channel shall be selected according to the following principles:

① Unclean and easy to scale fluids should go through the pipe side, because it is more convenient to clean in the pipe.

② Corrosive fluid should go through the tube side to avoid corrosion of tube bundle and shell at the same time.

③ The fluid with high pressure should go through the pipe side to avoid pressure on the shell.

④ The saturated steam should go through the shell side, because the heat transfer coefficient of steam condensation has nothing to do with the flow rate, and the condensate is easy to discharge.

3. Precautions and working principle of fixed tubesheet heat exchanger

- (1) The heat exchanger can only be used after pressure test after new installation or maintenance.

- (2) When starting the heat exchanger, the cold flow shall be followed by the heat flow, and when stopping the work, the heat flow shall be stopped first and then the cold flow. To prevent leakage or damage caused by uneven thermal expansion and cold contraction.

- (3) The fixed tubesheet heat exchanger is not allowed to be heated in one direction, and the temperature difference on both sides of the tube and shell of the floating heat exchanger is not allowed to be too large.

- (4) During startup, the exhaust valve shall be kept open to discharge all air, and shall be closed after startup.

- (5) If hydrocarbons are used, the air in the heat exchanger shall be removed with inert gas before loading hydrocarbons to avoid explosion.

- (6) During shutdown and purging, the condensate must be drained before steam introduction, and the air shall be ventilated slowly to prevent water hammer. When one side of the heat exchanger is ventilated, the vent valve on the other side must be opened to avoid damage to the pressure. When the heat exchanger is closed, the exhaust valve and drain valve shall be opened to prevent the equipment from being damaged by vacuum caused by cooling.

- (7) When using the air cooler, pay attention to the uniform flow of some parts to ensure the cooling effect.

- (8) Always pay attention to monitoring to prevent leakage.

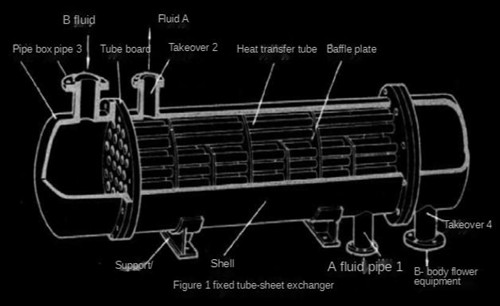

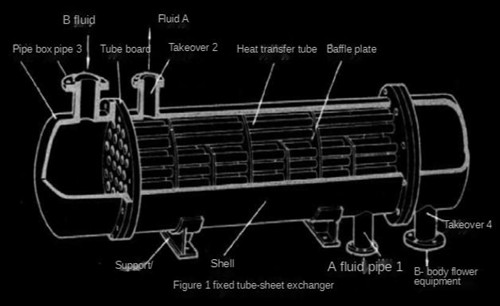

Working principle of fixed tubesheet heat exchanger:

It is the structure of fixed tubesheet heat exchanger. A fluid flows into the housing from the connecting pipe 1 and flows out from the connecting pipe 2 through the pipe. B fluid flows in from the connecting pipe 3 and out of the connecting pipe 4 through the pipe. If the temperature of fluid a is higher than that of fluid B, heat is transferred from fluid a to fluid B through the pipe wall; On the contrary, it is transferred from fluid B to fluid a through the pipe wall. The area inside the shell and outside the pipe and pipe box is called the shell side, and the fluid passing through the shell side is called the shell side fluid (a fluid). The area inside the pipe and the pipe box is called the pipe pass, and the fluid passing through the pipe pass is called the pipe pass fluid (B fluid). Shell and tube heat exchanger is mainly composed of tube box, tube plate, tube, shell and baffle. Generally, the shell is cylindrical and the pipe is straight or U-shaped. In order to improve the heat transfer efficiency of the heat exchanger, threaded tubes and finned tubes can also be used. The arrangement of pipes has many forms, such as equilateral triangle, square, square skew 45 ° and concentric circle. The first three are the most common. When arranged in a triangle, more tubes can be arranged in the shell with the same diameter to increase the heat transfer area, but it is difficult to clean the tubes mechanically and the fluid resistance is large. The overall of tubesheet and tube is called tube bundle. There are two types of connection between the end of the pipe and the tubesheet: welding and expansion. Some baffles are set transversely in the tube bundle to guide the shell side fluid to change the flow direction for many times and effectively scour the tube, so as to improve the heat transfer efficiency and support the tube at the same time. The shapes of baffles include bow, circle and rectangle. In order to reduce the flow cross section of shell side and tube side fluid, speed up the flow rate and improve the heat transfer efficiency, split partition plates can be set longitudinally in the tube box and shell, divide the shell side into 2 passes and the tube side into 2 passes, 4 passes, 6 passes and 8 passes.

4. Type and connection mode of floating head heat exchanger

One end of the tubesheet at both ends of the floating head heat exchanger is not connected with the shell, and this end is called floating head. When the tube is heated, the tube bundle and the floating head can expand and contract freely along the axial direction, completely eliminating the temperature difference stress. The floating head heat exchanger has a tubesheet at one end fixed with the shell, while the tubesheet at the other end can float freely in the shell. The shell and tube bundle are free from thermal expansion, so when the temperature difference between the two media is large, there will be no temperature difference stress between the tube bundle and the shell. The floating head end is designed into a detachable structure, so that the tube bundle can be easily inserted or pulled out, which provides convenience for maintenance and cleaning. This type of heat exchanger is especially suitable for working conditions where the temperature difference stress between the shell and the heat exchange tube is large and both the shell side and the tube side are required to be cleaned.

(1) Advantages of floating head heat exchanger:

- A the tube bundle can be pulled out to facilitate the cleaning of the tube and shell side.

- B. the temperature difference between media is not limited.

- C. It can work under high temperature and high pressure. Generally, the temperature is less than or equal to 450 degrees and the pressure is less than or equal to MPa.

- D. It can be used in occasions with serious scaling.

- E. it can be used in places where the pipe side is easy to corrode.

(2) Disadvantages of floating head heat exchanger:

- A small floating head is prone to internal leakage.

- B the consumption of metal materials is large and the cost is 20%.

- C complex structure.

(3) Selection requirements for parts and materials of floating head heat exchanger.

(4) Connection mode of heat exchange tube and tubesheet: the connection mode of heat exchange tube and tubesheet includes expansion, welding, expansion and welding, etc.

Expansion joint formation can be divided into sticking expansion and strength expansion according to expansion tightness. Sticking expansion refers to the slight expansion to eliminate the gap between heat exchange tube and tubesheet. Strength expansion refers to the expansion joint to ensure the sealing performance and tensile strength of the connection between heat exchange tube and tubesheet.

The welding connection between heat exchange tube and tubesheet is divided into strength welding and sealing welding. Strength welding refers to the welding to ensure the sealing performance and tensile strength of the connection between heat exchange tube and tubesheet. Seal welding refers to the welding to ensure the sealing performance of the connection between heat exchange tube and tubesheet. The welding of heat exchange tube and tube sheet generally adopts manual arc welding, manual sub arc welding and automatic rotating argon arc welding.

C. Expansion and welding

In terms of expansion welding connection process, it can be divided into expansion before welding and welding before expansion. Expansion and welding are suitable for occasions with high sealing performance requirements; Occasions bearing vibration or fatigue load; Occasions with interstitial corrosion; Where composite tubesheet is used.

(5) Selection of connection type between heat pipe and tubesheet

The application scope of strength expansion specified in GB150 pressure vessels is: the design pressure is less than or equal to 4MPa; Design temperature is less than or equal to 300 ° C; There is no violent vibration, excessive temperature change and obvious stress corrosion during operation. The application scope of strength welding is: it can be used for the design pressure specified in this standard, but it is not suitable for occasions with large vibration and interstitial corrosion. Expansion and welding are suitable for occasions with high sealing performance requirements; Occasions bearing vibration or fatigue load; Occasions with interstitial corrosion; Where composite tubesheet is used.

5. Reasonable selection of heat exchange medium and preliminary treatment method

Generally, scale inhibitor and algicide are added. If necessary, sulfuric acid is added to adjust the pH value. Pay attention to the hardness and pH value of circulating water, and timely adjust the dosage of scale inhibitor and sulfuric acid. Algicide is generally added by impact method. Pay attention to sewage discharge 1-2 days after algicide is added. If possible, the soft water treatment system can be used, but algicide must be added. Even so, some biological slime will adhere to the heat exchanger, and high-pressure water can be considered for cleaning. The agents added in the circulating water system are mainly bactericidal algicide and corrosion and scale inhibitor, which aims to improve the circulating water quality, slow down the corrosion of equipment and pipelines and prevent scaling in the heat exchanger, To increase the fouling thermal resistance, we should strictly control the relevant process parameters in the actual production process, hang hanging pieces at different points in the circulating water system, and properly adjust the agent according to the hanging piece corrosion.

6. Reduce and eliminate scale formation from the process control of heat exchanger operation

The process conditions of heat exchanger include heat transfer, thermodynamic parameters of fluid (temperature, pressure, flow, phase state, etc.) and physicochemical properties (density, viscosity, corrosivity, etc.). While ensuring heat transfer efficiency, minimize the conditions for scaling formation; The operation shall be carried out in strict accordance with the specifications. The general practice is:

(1) Increase the heat transfer coefficient. On the premise of comprehensively considering the fluid resistance and no fluid induced vibration, the high flow rate shall be selected as far as possible.

(2) Increase the average temperature difference. For the fluid without phase change, the heat transfer mode close to countercurrent shall be adopted as far as possible. Because this can not only improve the average temperature difference, but also help to reduce the temperature difference stress in the structure. Under allowable conditions, the inlet temperature of hot fluid can be increased or the inlet temperature of cold fluid can be reduced.

(3) Properly arrange the heat transfer surface. For example, heat exchangers, cold disks, etc. adopting appropriate tube spacing or arrangement can not only increase the heat transfer area in unit space, but also improve the fluid flow characteristics. The heat transfer mode of staggered tube bundle is better than that of parallel tube bundle.

(4) Cleaning method of formed scale

① Chemical method

The chemical method is to remove the scale by chemical reaction or loosen the scale by chemical reaction, and then remove it by external force. Of course, for chemical cleaning, it is best to ask an experienced professional company for cleaning. The cleaning cost is low. Before cleaning, analyze the scaling composition and formulate a detailed construction scheme. During cleaning, ensure that the chemical solution will not erode the heat exchange pipe and process pipeline.

② Mechanical method

- (a) High pressure water jet cleaning: generally, 1-5mpa pressure is used to form a strong jet through the spray gun nozzle, and the water volume reaches 80-120l / min to break and scour the scale layer to achieve the purpose of cleaning. At present, the manual hand-held flexible or rigid spray gun is basically used to flush the inner side of the heat transfer tube one by one, and the outer side of the tube bundle is rotated section by section to flush from multiple directions. In order to improve efficiency and reduce labor intensity, different spraying instruments shall be used according to the scale conditions, such as improving the nozzle (nozzle size, shape, quantity and angle). For some insoluble scale and blockage, special cleaning methods shall be adopted, such as high-pressure water jet drill bit or ultra-high-pressure water jet > 70MPa. Combined cleaning can also be carried out by reagent or heating.

- (b) Manual cleaning or pipeline mechanical cleaning brush: manual cleaning or pipeline mechanical cleaning brush is used to clean the inner wall of the pipe. This method has good adaptability and can be cleaned for many times, but attention must be paid not to damage the pipe wall.

③ Regular cleaning

In order to eliminate the scaling during the operation of the heat exchanger, the flow can be increased periodically and temporarily or countercurrent operation can be carried out, which can effectively eliminate the light attachments on the inner wall of the pipe, but the backwash pipeline shall be preset on the equipment. It can also be cleaned with rubber balls. Appropriate chemicals can also be injected according to the type of fluid to remove the dirt. Timely cleaning shall be carried out during each shutdown and maintenance, and the effect is the best.

④ Cleaning during parking

The shutdown cleaning of heat exchanger shall adopt different methods for different types of heat exchangers and scaling conditions, mainly including high-pressure water jet cleaning, chemical cleaning and mechanical cleaning. Mechanical cleaning is to manually pull through the strip or rotate the heat transfer pipe one by one with an electric drill bit. If the compressed oil cooler is overhauled, it shall be cleaned in time. It is not easy to clean for a long time, with high labor intensity and easy to damage the inner wall of the steel pipe.

Source: China Stainless Steel Flanges Manufacturer - Yaang Pipe Industry Co., Limited (www.yaang.com)