- Material: Stainless Steel 316L

- Technics: Cold Formed

- Type: Flame Arrester

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Application: General, Pipeline

- Pressure: 0.6- 5.0Mpa, 150Lb-600Lb

- Media: Oil

- SITEMAP

- CONTACT US

- 8618267732328

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

Stainless Steel 316L Explosion Proof Pipeline Flame Arrester 4 Inch CL150

- FOB PriceUSD 1 - 1,700/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

Packaging & Delivery

Packaging Details:

Seaworthy Wooden Case

Delivery Detail:

2 - 10 days according to the quantity and production plan

| Packaging Details: | Seaworthy Wooden Case |

|---|---|

| Delivery Detail: | 2 - 10 days according to the quantity and production plan |

Specifications

Stainless Steel 316L Explosion Proof Pipeline Flame Arrester

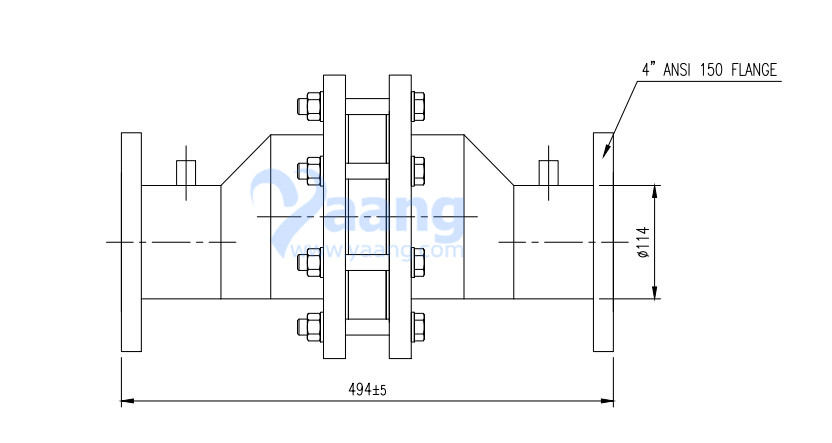

1) Size: 4" ANSI 150 Flange x 4" ANSI 150 Flange

2) Installation type: Middle of pipe

3) Material: Stainless Steel 316L

4) Type: Flame Arrester

Stainless Steel 316L Explosion Proof Pipeline Flame Arrester is passive devices with no moving parts. They prevent the propagation of flame from both the exposed side of the unit to the protected side by the use of wound crimped metal ribbon type flame cell element. This Construction produces a matrix of uniform openings that are carefully constructed to quench the flame by absorbing the heat of the flame. This provides an extinguishing barrier to theignited vapor mixture.

Stainless Steel 316L Explosion Proof Pipeline Flame Arrester

1) Size: 4" ANSI 150 Flange x 4" ANSI 150 Flange

2) Installation type: Middle of pipe

3) Material: Stainless Steel 316L

4) Type: Flame Arrester

Stainless Steel 316L Explosion Proof Pipeline Flame Arrester is passive devices with no moving parts. They prevent the propagation of flame from both the exposed side of the unit to the protected side by the use of wound crimped metal ribbon type flame cell element. This Construction produces a matrix of uniform openings that are carefully constructed to quench the flame by absorbing the heat of the flame. This provides an extinguishing barrier to theignited vapor mixture.

Composition ranges For 316L Stainless Steel

Grade |

|

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

316L |

Min |

- |

- |

- |

- |

- |

16.0 |

2.00 |

10.0 |

- |

Max |

0.03 |

2.0 |

0.75 |

0.045 |

0.03 |

18.0 |

3.00 |

14.0 |

0.10 |

Process Of 316L Flame Arrester:

Stainless Steel 316L Explosion Proof Pipeline Flame Arrester blocks the propagation of flame passing through it. The heat of flame is absorbed by the flame element where very high surface area is provided for immediate heat transfer.

It has no moving parts and the custom designed flame element gives the necessary protection from flame flash back. Whereas the flame propagation is blocked through the flame elements, the gases can pass through them easily have minimum pressure drop. This is ensured by having large flow area available to gases in flame blank.

Under normal operating conditions the flame arrestor permits a relatively free flow of gas or vapor through the piping system. If the mixture is ignited and the flame begins to travel back through the piping, the arrestor will prohibit the flame from moving back to the gas source. It has wound crimped metal ribbon type flame cell element which has the dimensions below MSEG of the liquid or vapor and hence arrests the flow of flame front through it & hence prohibits further flow of flame if any.

Main Features Of 316L Flame Arrester:

Fully customized & cost effective solutions as per project requirements.

Covering long life and least maintenance.

Suitable for application in gas groups I,IIA and IIB.

Provision for Temperature Sensor, Drain and Cleaning Ports.

Minimum pressure drop.

High flow capacity and Quick Quenching of flame.

Wide choice of Materials and Customized Design also available.

Easy Maintenance.

Simple and rigid design.

Applications Of 316L Flame Arrester:

Flammable Gas/ Liquid Storage Tank Vents.

Coal Mine ventilation systems.

Offshore Drilling Platform Vents.

Vapor Inclination Systems

Feed to Burners.

Chemical and Petrochemical Process Plant.

Agro-chemicals and fertilizers industry.

Gas pressure regulators.

Sewage Digester plant.

Vapor Recovery Systems.

Sewage and Waste water Treatment

Combustible gas pipe

Oilcan with deposited petroleum

Vent pipe

Oil gas recovery system

Combustible gas net

Exhaust of internal-combustion engine

Torch assembly system

We design and manufacture as per international standard.

Our products can be seen operating in refineries & petrochemical, pharmaceutical, chemical, marine, steel & various process industries.

Our products have exported our products to Africa ,Middle East & Asian countries

Our Quality Control facilities include trained personnel and calibrated instruments.

Process Of 316L Flame Arrester:

Stainless Steel 316L Explosion Proof Pipeline Flame Arrester blocks the propagation of flame passing through it. The heat of flame is absorbed by the flame element where very high surface area is provided for immediate heat transfer.

It has no moving parts and the custom designed flame element gives the necessary protection from flame flash back. Whereas the flame propagation is blocked through the flame elements, the gases can pass through them easily have minimum pressure drop. This is ensured by having large flow area available to gases in flame blank.

Under normal operating conditions the flame arrestor permits a relatively free flow of gas or vapor through the piping system. If the mixture is ignited and the flame begins to travel back through the piping, the arrestor will prohibit the flame from moving back to the gas source. It has wound crimped metal ribbon type flame cell element which has the dimensions below MSEG of the liquid or vapor and hence arrests the flow of flame front through it & hence prohibits further flow of flame if any.

Main Features Of 316L Flame Arrester:

Fully customized & cost effective solutions as per project requirements.

Covering long life and least maintenance.

Suitable for application in gas groups I,IIA and IIB.

Provision for Temperature Sensor, Drain and Cleaning Ports.

Minimum pressure drop.

High flow capacity and Quick Quenching of flame.

Wide choice of Materials and Customized Design also available.

Easy Maintenance.

Simple and rigid design.

Applications Of 316L Flame Arrester:

Flammable Gas/ Liquid Storage Tank Vents.

Coal Mine ventilation systems.

Offshore Drilling Platform Vents.

Vapor Inclination Systems

Feed to Burners.

Chemical and Petrochemical Process Plant.

Agro-chemicals and fertilizers industry.

Gas pressure regulators.

Sewage Digester plant.

Vapor Recovery Systems.

Sewage and Waste water Treatment

Combustible gas pipe

Oilcan with deposited petroleum

Vent pipe

Oil gas recovery system

Combustible gas net

Exhaust of internal-combustion engine

Torch assembly system

We design and manufacture as per international standard.

Our products can be seen operating in refineries & petrochemical, pharmaceutical, chemical, marine, steel & various process industries.

Our products have exported our products to Africa ,Middle East & Asian countries

Our Quality Control facilities include trained personnel and calibrated instruments.

Where can we find the high quality Stainless Steel 316L Explosion Proof Pipeline Flame Arrester.

Where can we find the high quality Stainless Steel 316L Explosion Proof Pipeline Flame Arrester.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

If any inquiry, please feel free to contact by email [email protected]

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.