Ξ

- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

PRODUCT SERIES

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Your Location: Home > News

News - Yaang

What are the common corrosion of stainless steel?

DataTime:[2017-1-15]

In the field of widely used, the corrosion resistance of stainless steel are satisfactory. From experience, in addition to the mechanical failure, the corrosion of stainless steel mainly displays in: the a serious corrosion of stainless steel in the form of local corrosion (i.e. stress corrosion cracking, pitting corrosion, intergranular corrosion, crevice corrosion and corrosion fatigue). A lot of stainless steel corrosion failure accidents is actually can be avoid by reasonable selection and.

Stress corrosion cracking (SCC)

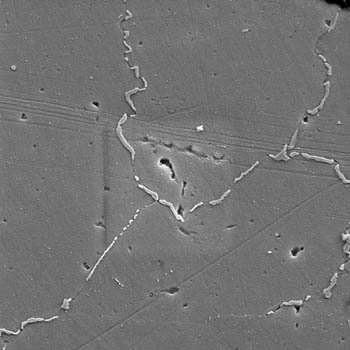

Stress corrosion cracking refers to stainless steel under stress because of crack extension and failure in the corrosive environment. Stress corrosion cracking of brittle fracture morphology and toughness of material can also occur in. Stress corrosion cracking of the necessary factors is to have a tensile stress, residual stress, and stress) and the corresponding corrosive medium. Crack formation and propagation is roughly and vertical tensile stress direction. This leads to stress value of the stress corrosion cracking than when there are no corrosive medium stress value of the material fracture need much smaller. In the micro level, through the crack in grain called transgranular crack, and the cracks along the grain boundary expansion graph called the intergranular crack, when the stress corrosion cracking extended to one depth (here, the load stress on the section of materials to achieve its fracture stress) in the air, the material is according to the normal crack (in ductile material, usually through microscopic defect aggregation) and disconnect. Therefore, as a result of the stress corrosion cracking and failure parts section, will contain area has the characteristics of the stress corrosion cracking and polymerization with micro defects have associated "toughening nest" area.

Pitting corrosion

Corrosion is a form of local corrosion.

Intergranular corrosion

Grain boundary are crystal orientation in different intergranular disorder malocclusion boundaries, so they are stainless steel of various elements of solute segregation or metal compounds (e.g., carbide and delta facies) precipitate out the favorable area. In some corrosive medium, grain boundary may first be corrosion is not surprising. This type of corrosion is known as intergranular corrosion, most of the metal and stainless steel in specific corrosive medium are intergranular corrosion may occur.

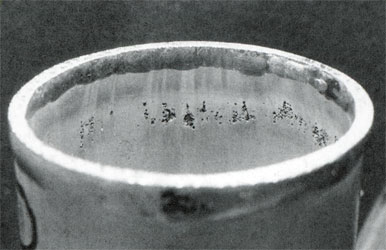

Crevice corrosion

Crevice corrosion is a kind of local corrosion performance, it may occur in the gap of stagnation of solution or in a surface. Metal and metal or metal and non-metal joint can form such a gap, for example, with rivets, bolts, gaskets, valve seat, the surface of the loose sediment and Marine biological phase formation.

General corrosion

General corrosion refers to the entire stainless steel surface corrosion phenomenon in the form of comparison are a spoon. Is general corrosion, the village of material thinning due to corrosion, and even the final failure due to corrosion. Stainless steel in strong acid and strong alkali corrosion is likely to be comprehensive.

All kinds of stainless steel corrosion resistance

304 stainless steel is a kind of common stainless steel, is widely used in production requirements with good comprehensive performance, corrosion resistance and formability of equipment and parts.

301 stainless steel during deformation presents obvious work hardening phenomenon, a high intensity was used for various occasions.

302 stainless steel is essentially higher variations of 304 stainless steel, the carbon content by cold rolling can make its higher strength.

302 b is a kind of high silicon content in stainless steel, it has high resistance to high temperature oxidation performance.

Se is 303 and 303 respectively containing sulfur and selenium free cutting stainless steel, used for main requirements with high degrees of free cutting and table light hao occasion. 303 se stainless steel is also used to make part of the need of hot upsetting, because in such conditions, the stainless steel has good hot workability.

304 l is a variation of carbon content lower 304 stainless steel, welding is applied to the occasion. Low carbon content is made in the heat affected zone near the weld in the precipitation of carbide to a minimum, because of the carbide precipitation may result in stainless steel intergranular corrosion in some environments (welding erosion).

304 n is a kind of nitrogenous stainless steel, and the effect of nitrogen is to improve the strength of the stainless steel.

In 305 and 384 stainless steel containing high nickel, the work hardening rate is low, suitable for various occasions requiring cold formability.

308 stainless steel are mainly used for making electrode.

309, 310, 314 and 330 stainless steel and nickel, chromium content is higher, mainly for stainless steel in high temperature oxidation resistance and creep strength. And 30 s5 and 310 s was 309 and 310 stainless steel varieties, the difference is only carbon content is low, in order to minimize the carbide precipitation near the weld. 330 stainless steel has a particularly high carburizing resistance and thermal shock resistance.

317 and 316 stainless steel containing aluminum, thus in the ocean of pitting corrosion resistance and chemical industrial environment is greatly better than that of 304 stainless steel. Among them, the varieties, including low carbon type 316l stainless steel, nitrogen stainless steel of high strength 316 n and high sulfur content of free cutting stainless steel 316 f.

321, 347 and 348 was on titanium, niobium and tantalum and niobium, stabilization of stainless steel, suitable for high temperature use welded components. 348 is a stainless steel is suitable for the nuclear power industry, has a certain restrictions on the content of tantalum and drilling.

Source: Yaang Pipe Industry Co., Limited (www.yaang.com)

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.