CLASS 3000

| NPS | A | B | C | D | E |

| 1/2 | 1 25.40 |

1.13/32 35.71 |

29/32 23.01 |

0.622 15.80 |

9/16 14.28 |

| 3/4 | 1.1/16 26.98 |

1.23/32 43.65 |

1.5/32 29.36 |

0.824 20.93 |

9/16 14.28 |

| 1 | 1.5/16 33.33 |

2 50.8 |

1.7/16 36.51 |

1.049 26.64 |

25/32 19.84 |

| 1¼ | 1.5/16 33.33 |

2.9/16 65.08 |

1.3/4 44.45 |

1.380 35.05 |

3/4 19.05 |

| 1½ | 1.3/8 34.92 |

2.27/32 72.23 |

2 50.8 |

1.610 40.89 |

3/4 19.05 |

| 2 | 1½ 38.1 |

3.15/32 88.10 |

2.9/16 65.08 |

2.067 52.50 |

13/16 20.63 |

| 2½ | 1.9/16 39.68 |

4.1/16 103.18 |

3 76.2 |

2.469 62.71 |

3/4 19.05 |

| 3 | 1.3/4 44.45 |

4.13/16 122.23 |

3.11/16 93.66 |

3.068 77.93 |

15/16 23.81 |

| 3½ | 1.11/16 42.86 |

5.3/8 136.52 |

4.7/16 112.71 |

3.548 90.12 |

11/16 17.46 |

| 4 | 1.7/8 47.62 |

5.31/32 151.60 |

4.3/4 120.65 |

4.026 102.26 |

1.1/16 26.98 |

| 5 | 2.5/8 66.67 |

7.5/16 185.73 |

5.9/16 141.28 |

5.047 128.19 |

1.11/32 34.13 |

| 6 | 2.3/4 69.85 |

8.5/8 219.07 |

6.11/16 169.86 |

6.065 154.05 |

1.13/32 35.71 |

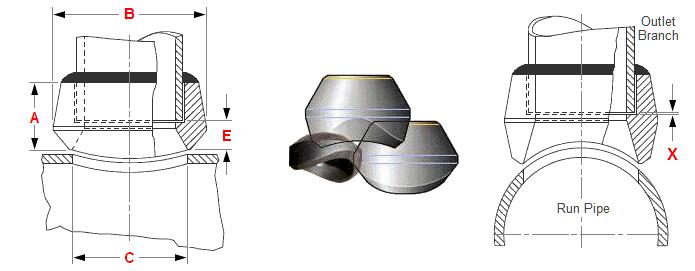

| X = Min. 1/16 (1.6 mm) | |||||

CLASS 6000

| NPS | A | B | C | D | E |

| 1/2 | 1¼ 31.75 |

1.23/32 43.65 |

3/4 19.05 |

0.466 11.84 |

7/8 22.22 |

| 3/4 | 1.7/16 36.51 |

1.61/64 49.60 |

1 25.4 |

0.614 15.60 |

7/8 22.22 |

| 1 | 1.9/16 39.68 |

2.7/16 61.91 |

1.5/16 33.33 |

0.815 20.70 |

15/16 23.81 |

| 1¼ | 1.5/8 41.27 |

2.23/32 69.05 |

1½ 38.1 |

1.160 29.46 |

13/16 20.63 |

| 1½ | 1.11/16 42.86 |

3¼ 82.55 |

1.15/16 49.21 |

1.338 33.99 |

7/8 22.22 |

| 2 | 2.1/16 52.38 |

4.1/32 102.39 |

2.3/4 69.85 |

1.689 42.90 |

1.3/16 30.16 |

| X = Min. 1/16 (1.6 mm) | |||||

- Dimensions: Top Row in Inches / Bottom Row in millimeters.

- Bottoming Clearance - X - The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal, and to allow for differential expansion of the mating elements.

- Socket dimensions are in accordance with ASME B16.11. Design per MSS SP-97.

- Source comes from Bonney Forge (except the sizes in millimeters).

- Sockolet® is a registered name. Another often used name is Socket Weld Outlet.