- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

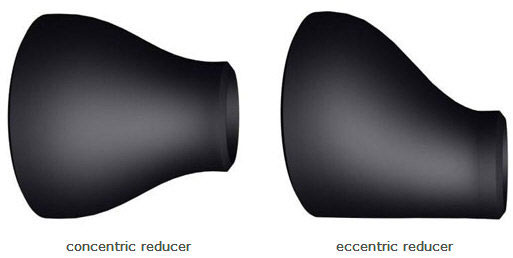

Butt Weld Fittings: Concentric Reducer/ Eccentric Reducer

Reducers be applied, to change from pipe diameter in one direction.

Standard there are 2 possibilities, the concentric reducer, is usually used in vertical pipe lines, and the eccentric reducer that is used in horizontal pipe lines.

TF & BF

On an isometric view, in a horizontal line, with a eccentric reducer must be declared, or the flat side at the bottom or top must be assembled. Perhaps, you have ever seen on a drawing, the abbreviation "TF" or "BF". This stands for respective "top flat" and "bottom flat"

LENGTH OF REDUCERS

The length of a Reducer is very short in relation to the diameter, so in some dimensions the transition from one to another diameter is very abruptly. For example, a reducer 6" x 2½" has a length of 140 mm. On this short distance a pipeline will be reduced from 168.3 mm O.D. to 73 mm O.D. During the design phase of a new pipe system, a piping designer certainly must think about it.

An alternative for a smoother flow would be to apply multiple reducers like:

- 6" x 5" (L=140 mm)

- 5" x 4" (L=127 mm)

- 4" x 3½" (L=102 mm)

- 3½" x 3" (L=102 mm)

- 3" x 2½" (L=102 mm)

So, now the distance is approximately 573 mm if the 6" pipe is reduced to 2½" inches, and and a smoother flow is guaranteed.

In practice this example will probably never occur, I hope, no no, I′m sure, there are better designers like me.

- Bottom flat eccentric reducer is often be used in pipe racks to keep the pipeline at the same elevation, after a pipe size change. When a concentric or a flat on top eccentric reducer in a pipe rack will be used, the support detail, probably change.

- Top flat eccentric reducer are often be used in pump suction lines to avoid accumulation of gas pockets.Eccentric reducers can avoid small "dead spots" that exist behind concentric reducers.

Some draughtsmen also specify the size difference T between the center lines. As a eccentric reducer in a vertical line is used, it may also be important, which side should be oriented to the north, south, east or west.

Dimensions and dimensional tolerances of welding reducers

Reducers are mainly used as part of pipelines in the construction, energy engineering and mining industry. Dimensions of tube reducers are: outside diameter of 26.9 -114, 3 mm, wall thickness from 2.3 to 3.6 mm, NPS 3/4 – 4 Steel for butt welding reducers Reducers are made from carbon and low alloy steels, dimensional tolerances are in accordance with relevant standards.

Heat treatment, condition of delivery and surface

The input tubes used for production of reducers are heat treated. Reductions are delivered with the inner and outer surface descaled not preserved, without surface protection or with surface treated by blasting.

Ends customization of the reducers

Upon agreement it is possible to supply reducers with a wall thickness of more than 3 mm with adjustment for a weld according to DIN 2559 standard.

Testing of weld reducers

The input tubes and ready made reducers are tested according to requirements and the appropriate standards.

Marking of the weld reducers

Reducers are marked as required by standards or agreement. Marking is done usually by stamping the agreed data. Packaging of weld reducers Reducers are packaged in cardboard boxes or metal pallets.

Certificates for weld reducers Certificates are issued according to either DIN 50049 or EN 10204 standards.

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.