- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Key points of welding process for 2205 duplex stainless steel

In the process of stainless steel processing, the welding of 2205 duplex stainless steel is a very test welding technology. This article will pay attention to the welding process of this kind of stainless steel.

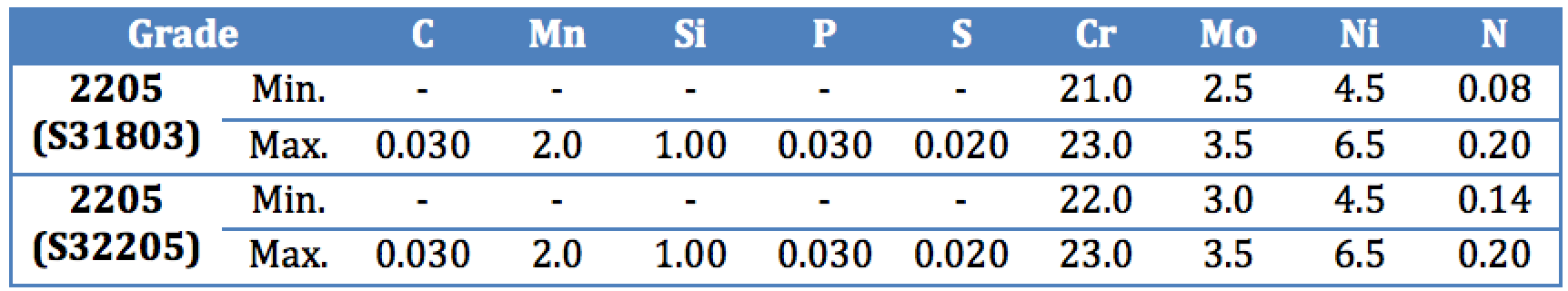

People usually call for the second generation of double phase stainless steel standard duplex stainless steel, its composition is characteristic of ultra low carbon and nitrogen, the typical composition of the steel is 22% chromium, 5% nickel, 0.17% nitrogen, compared with the first generation of double phase stainless steel, 2205 stainless steel to improve nitrogen content, enhance the concentration of chloride ion in acidic medium the higher the resistance to stress corrosion and pitting corrosion resistance. Nitrogen is a strong element of austenite formation. When added to duplex stainless steel, it can not only improve the strength, but also do not damage the plasticity and toughness of stainless steel, and also inhibit the precipitation of carbides.

The microstructure of 2205 duplex stainless steel is remarkable. In the greenhouse, the austenite and ferrite in the solid solution of steel are about half of each, both of which have the characteristics of two-phase structure. The retained ferrite stainless steel small coefficient of thermal conductivity, corrosion, crevice and chloride features, stress corrosion of austenitic stainless steel has good toughness, brittle transition temperature is low, the resistance to intergranular corrosion, mechanical properties and welding performance.

In addition, the performance is outstanding. The yield strength and stress corrosion resistance of dual phase stainless steel are nearly 1 times higher than that of austenitic stainless steel, and the material can be effectively saved under the same pressure grade condition. The coefficient of linear thermal expansion of austenitic stainless steel is lower than that of low carbon steel. Therefore, duplex stainless steel is suitable for joining with carbon steel, and its engineering significance is great. But forging and cold stamping are inferior to austenitic stainless steel.

The weldability of duplex stainless steel 2205 is good, and the sensitivity of welding cold crack and hot crack is smaller. Generally, there is no need to preheat before welding and no heat treatment after welding. Because of the higher nitrogen content, the single-phase ferrite tendency in the heat affected zone is smaller. When the welding material is selected reasonably and the welding line energy is controlled at the time, the welding head has good comprehensive performance.

The thermal crack sensitivity of 2205 duplex stainless steel is much lower than that of austenitic stainless steel. This is because the nickel content is not high, easy to form low melting point eutectic impurities very few, it is difficult to produce low melting point liquid film. In addition, the grain does not grow rapidly at high temperature.

In addition, the main problem of duplex stainless steel welding is not in the weld, but in the heat affected zone. Due to the thermal cycling, the heat affected zone is in a fast cooling non equilibrium state. After cooling, more ferrite is retained, which increases the corrosion tendency and the susceptibility to hydrogen induced cracking (brittleness).

In the process of duplex stainless steel welding, the microstructure of weld metal and heat affected zone undergo a series of changes under the action of thermal cycling. The microstructure of all duplex stainless steels is composed of ferrite at high temperature, and austenite is precipitated during cooling. The precipitation of austenite is affected by many factors.

The mechanical properties and corrosion resistance of the duplex stainless steel welded joint are affected by the proper proportion of the welded joint, so the welding is centered on how to ensure the duplex structure of the welded joint. When the amount of ferrite and austenite is close to 50%, the properties are good and close to the properties of base metal. If this relationship changes, the corrosion resistance and mechanical properties of the duplex stainless steel welded joint shall be reduced. Duplex stainless steel 2205 best 45% ferrite content is too low, the ferrite content is less than 25% will result in strength and resistance to stress corrosion cracking ability should be decreased; the high ferrite content greater than 75% will be detrimental to the corrosion resistance and impact toughness decrease.

The first phase stainless steel welding factors affected the proportion is mainly depends on the balance between the welding joint of ferrite and austenite, which is influenced by the content of alloying elements in steel, and by the filler metal, welding heat cycle, protective gas.

The most important feature of duplex stainless steel welding is that the welding thermal cycle has an influence on the microstructure of the welded joint, and the phase transformation will occur in both the weld and the heat affected zone, which will affect the performance of the welded joint to a great extent. So the multipass welding is good, has the effect of heat treatment on subsequent weld bead front, weld metal ferrite further transformed into austenite and become dominant in two phases of austenite; heat affected zone adjacent to the weld in the austenite phase also increased accordingly, and can reduce the grain refinement of ferrite carbide and from the nitride and grain boundary precipitates.

The welding process number is the welding line energy, also plays the key role to the dual phase organization balance. Because duplex stainless steel is 100% ferrite at high temperature, if the line energy is too small, the heat affected zone cooling rate is fast, the austenite is not enough to precipitate, and the excessive ferrite will remain cool under the greenhouse. If the line energy is too large, the cooling rate is too slow, although you can get sufficient austenite, but it may also cause the heat affected zone of ferrite precipitated grains and sigma phase harmful metal phase, resulting in the formation of joint embrittlement. To prevent this from happening, the best measure is to control the welding line energy and the interlayer temperature, and fill the metal with filler metal.

Source: China Pipe Fittings Manufacturer - Yaang Pipe Industry Co., Limited (www.yaang.com)

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.