Ξ

- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

PRODUCT SERIES

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Your Location: Home > News

News - Yaang

The role of titanium in steel

DataTime:[2020-6-6]

Effect of titanium on Microstructure and heat treatment of steel

- ① Titanium has strong affinity with nitrogen, oxygen and carbon. It is a good deoxidizer and an effective element for fixing nitrogen and carbon.

- ② Titanium and carbon compounds (TIC) have strong binding force and high stability. Only when heated above 1000 ℃ can it slowly dissolve into the solid solution of iron. TiC particles can prevent the grain growth and coarsening of steel.

- ③ Titanium is one of the forming elements of strong ferrite, which makes the austenite phase area narrow. Solid solution titanium improves the hardenability of steel, while the presence of TiC particles reduces the hardenability of steel.

- ④ When titanium content reaches a certain value, precipitation hardening can be produced due to dispersion precipitation of tife2.

Effect of titanium on mechanical properties of steel

- ① When titanium exists in ferrite as a solid solution, its strengthening effect is higher than that of aluminum, manganese, nickel, molybdenum, etc., and lower than that of beryllium, phosphorus, copper and silicon.

- ② The influence of titanium on the mechanical properties of steel depends on its morphology, the ratio of Ti to C and the heat treatment method. When the content of Ti is in the range of 0.03% ~ 0.1%, the yield strength can be increased, but when the ratio of Ti to C is more than 4, the strength and toughness of Ti decrease sharply.

- ③ Titanium can improve the endurance strength and creep resistance.

- ④ Titanium can improve the toughness of steel, especially the impact toughness at low temperature.

Effect of titanium on physical, chemical and technological properties of steel

- ① Improve the stability of steel in high temperature, high pressure and hydrogen.

- ② Titanium can improve the corrosion resistance of stainless and acid resistant steel, especially the resistance to intergranular corrosion.

- ③ In low carbon steel, when the ratio of Ti to C is more than 4.5, because oxygen, nitrogen and carbon are all fixed, it has good stress corrosion resistance and alkali embrittlement resistance.

- ④ The oxidation resistance of the steel at high temperature can be improved by adding titanium to the steel with chromium content of 4% - 6%.

- ⑤ Titanium can promote the formation of nitriding layer and obtain the required surface hardness quickly. Titanium containing steel is called "fast nitriding steel" and can be used to make high-precision screws.

- ⑥ Improve the weldability of low carbon manganese steel and high alloy stainless sodium.

Application of titanium in steel

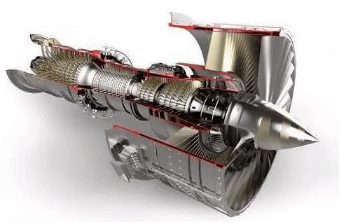

Titanium alloy aircraft turbine

- ① When the mass fraction of titanium exceeds 0.025%, it can be considered as alloy element.

- ② Titanium, as an alloy element, is widely used in common low alloy steel, alloy structural steel, alloy tool steel, high-speed tool steel, stainless and acid resistant steel, heat-resistant and non peeling steel, permanent magnet alloy and cast steel.

- ③ Titanium has been used as a variety of advanced materials and has become an important strategic material, accounting for more than half of the use in the aerospace industry, such as aerospace vehicles, power machinery, etc.

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.