- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Types of Flange Face

With flange Face the form and implementation of the side of a flens are meant, where a sealing ring or gasket will be placed. The most used types are:

2. Flat Face (FF)

3. Ring-Type Joint (RTJ)

4. Male-and-Female (M&F)

5. Tongue-and-Groove (T&G)

• RAISED FACE (RF)

The Raised Face type are the most applied flange type, and is easily to identify. It is referred to as a raised face because the gasket surfaces are raised above the bolting circle face.

Diameter and height are in ASME B16.5 defined, by Pressure Class and diameter. The height in Pressure Class up to 300 Lbs is approximately 1.6 mm, and in Pressure Class 400 up to 2500 Lbs the height is approximately 6.4 mm.

Pressure rating of the flange determines the height of the raised face.

The purpose of a RF flange is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint.

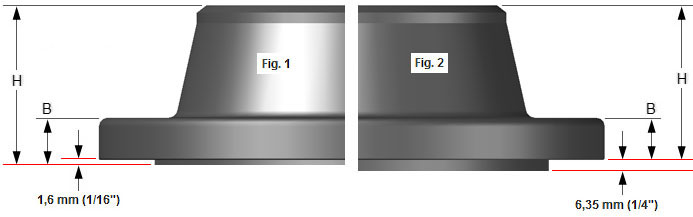

Raised Face height

For the height measures H and B of all described dimensions of flanges on this website, with exception of the Lap Joint flange, it is important to understand and remember the following:

In Pressure Classes 150 and 300 Lbs, the height of raised face is approximately 1.6 mm (1/16 inch).

In these two Pressure Classes, almost all suppliers of flanges, show in their catalog or brochure, the H and B dimensions including the raised face height. See figure 1 on the image below.

In Pressure Classes 400, 600, 900, 1500 & 2500 Lbs, the height of raised face is approximately 6.4 mm (1/4 inch). In these Pressure Classes, most suppliers show the H and B dimensions excluding the raised face height. See figure 2 on the image above.

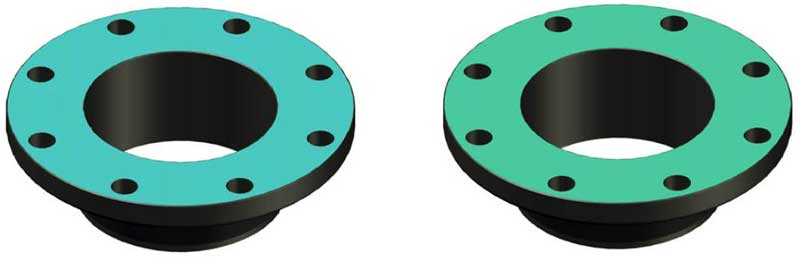

• FLAT FACE (FF)

The flat face (full face) flange has a gasket surface in the same plane as the bolting circle face. Applications using flat face flanges are frequently those in which the mating flange or flanged fitting is made from a casting.

Flat face flanges are never to be bolted to a raised face flange. ASME B31.1 says that when connecting flat face cast iron flanges to carbon steel flanges, the raised face on the carbon steel flange must be removed, and that a full face gasket is required. This is to keep the thin, bittle cast iron flange from being sprung into the gap caused by the raised face of the carbon steel flange.

• RING-TYPE JOINT (RTJ)

RTJ flanges have grooves cut into their faces which steel ring gaskets. The flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or Coining) the gasket to make intimate contact inside the grooves, creating a metal to metal seal.

An RTJ flange may have a raised face with a ring groove machined into it. This raised face does not serve as any part of the sealing means. For RTJ flanges that seal with ring gaskets, the raised faces of the connected and tightened flanges may contact each other. In this case the compressed gasket will not bear additional load beyond the bolt tension, vibration and movement cannot further crush the gasket and lessen the connecting tension.

Ring Type Joint gaskets are metallic sealing rings, suitable for high-pressure and high-temperature applications. They are always applied to special, accompanying flanges which ensure good, reliable sealing with the correct choice of profiles and material.

Ring Type Joint gaskets are designed to seal by "initial line contact" or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the "softer" metal of the gasket flows into the microfine structure of the harder flange material, and creating a very tight and efficient seal.

The most applied rings are:

1. Type R-Oval according to ASME B16.20

The original style of metallic ring joint. Used on round bottomed groove flanges though can also be used on later, flat-bottomed groove flanges. Suitable for ASME B16.5 flanges from Class 150 to 2500.

2. Type R-Octagonal according to ASME B16.20

An improved design over the original Oval design. However these can be used only in flat-bottomed groove flanges. Suitable for ASME B16.5 flanges from Class 150 to 2500.

• MALE-AND-FEMALE (M&F)

With this type the flanges must be matched. One flange face has an area that extends beyond the normalflange face (Male). The other flange or mating flange has a matching depression (Female) machined into it′s face.

Custom male and female facings are commonly found on the heat exchanger shell to channel and coverflanges.

• TONGUE-AND-GROOVE (T&G)

With this type the flanges also must be matched. One flange face has a raised ring (Tongue) machined onto the flange face while the mating flange has a matching depression (Groove) machined into it′s face.

These facings are commonly found on pump covers and valve bonnets.

General flange faces such as the RTJ, T&G and the F&M shall never be bolted together. The reason for this is that the contact surfaces do not match and there is no gasket that has one type on one side and another type on the other side.

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.