- SITEMAP

- CONTACT US

- 8618267732328

News

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

What is threaded flange?

A threaded flange is a connecting device that can be secured to a length of pipe without welding. Using a tapered thread, the threaded flange is tightened onto the pipe without leaking, however, a seal weld is commonly used, when appropriate. The nature of the threaded connection makes the threaded flange a viable option when welding is not feasible, such as highly flammable or explosive areas. This flange is commonly used only on smaller diameter pipes.

Threaded Flange Definition:

Threaded flange means the inner bore of a flange is thread, the shape of the threaded flange is like a slip on flange ,so the threaded flange could be plate shape or with a hub for longer thread.

Threaded Flange Joint:

The threaded pipe flange is connected to a pipe with a external thread on the pipe end , so the flange thread should have same thread specification with the pipe thread, the advantage of a threaded flange is that the piping system would be easily to assembly because there is no welding in this piping joint.

Sealing of a Threaded Flange:

The Threaded flanges are usually supplied with a raised face (RF) or flat face (FF) sealing face. When a raised face is necessary for threaded pipe flanges, the standard height should be 1/16″ for the face under class400, If the threaded pipe flanges is same or more than class 400 , the standard threaded pipe flange raised face height should be 1/4″.

The threaded pipe flange commonly used in a small sizes and not very high pressure situation. The threaded flange is no welding in the joint ,it means the flange could be used for some situations which is not able to arrange a welding work.

Size

Threaded flange:1/4″-6″

DN8-DN150

Pressure

America Series:Class 150 ,Class 300, Class 600, Class 900A ,Class 1500,Class 2500.

Europe Series:PN2.5,PN6,PN10,PN16,PN25,PN40,PN63,PN100,PN160,PN250,PN320,PN400.

Flange Facing Types

America Series:Flat face(FF),Raised face(RF),Tongue(T),Groove(G),Female(F),Male(M),Ring type joints face(RJ/RTJ)

Europe Series:Type A(Flat Face),Type B(Raised Face),Type C(Tongue),Type D(Groove),Type E(Spigot),Type F(Recess),Type G(O-Ring Spigot),Type H(O-Ring Groove)

Material

Carbon steel: ASTM A105,ASTM A105N,GB 20,C22.8.

Alloy steel: ASTM/ASME A182 F1-F12-F11-F22- F5-F9- F91

Stainless steel: ASTM/ASME A182 F304-304L-304H-304LN-304N

ASTM/ASME A182 F316-316L-316H-316LN-316N-316Ti

ASTM/ASME A182 F321-321H, F347-347H

Low temperature steel: ASTM/ASME A350 LF2.

High performance steel: ASTM/ASME A694 F42 , F52, F56, F60, F65, F70

Standards

ASME ANSI B16.5,ASME ANSI B16.47.

API 605,API 6L.

MSS SP 44

CSA Z245.12

EN1092-1,EN1759-1.

DIN2565, DIN2566, DIN2567, DIN2568, DIN2569

BS1560,BS 4504,BS 10.

AFNOR NF E29-200-1

ISO7005-1

AS2129

JIS B2220

UNI 2276. UNI 2277.UNI 2278 .UNI 6089 .UNI 6090

Industrial Processes

Die forging,Machining.

Uses of threaded flanges :

- Threaded flanges can be fitted to pipes of various sizes without welding and this is one chief benefit for which these flanges are highly demanded.

- They can be used in extremely high pressure applications, particularly at or near atmospheric temperature, where the necessary post weld heat treatment is not possible.

- They are ideal for small diameter piping applications.

- They are economical and time saving devices.

- These threaded flanges are normally designed for non-cyclic applications.

- The flanges are suitable to be used in applications where welding is hazardous.

- They can be used in highly explosive areas.

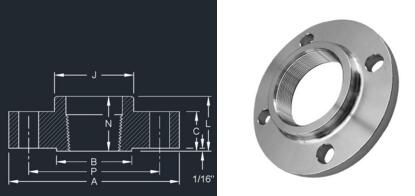

FLANGE - THREADED, ANSI CLASS 150, ASME B16.5, 1/16" RAISED FACE (IN) DATASHEET

This datasheet is for flanges that have athreaded flanges that have a raised face end connection.

- Dimensions and tolerances in accordance with ANSI/ASME B16.5 for sizes 1/2" to 24".

- When using carbon steel, forgings to be in accordance with ASTM A105.

- Flanges are tapped with American National Standard taper pipe threads.

- Bolt circle diameters are 1/8 inch larger than bolt diameter.

| Pipe Size (NPS) |

Outside Diameter of Flange A |

Diameter of Raised Face B |

Thickness of Flange C |

Diameter of Hub at Base J |

Length of Hub L |

Minimum Thread Length N |

Number of Bolt Holes

|

Diameter of Bolt Holes

|

Bolt Circle Diameter P |

Approx. Weight (Lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 3 1/2 | 1 3/8 | 7/16 | 1 3/16 | 5/8 | 5/8 | 4 | 5/8 | 2 3/8 | 2 |

| 3/4 | 3 7/8 | 1 11/16 | 1/2 | 1 1/2 | 5/8 | 5/8 | 4 | 5/8 | 2 3/4 | 2 |

| 1 | 4 1/4 | 2 | 9/16 | 1 15/16 | 11/16 | 11/16 | 4 | 5/8 | 3 1/8 | 2 |

| 1 1/4 | 4 5/8 | 2 1/2 | 5/8 | 2 5/16 | 13/16 | 13/16 | 4 | 5/8 | 3 1/2 | 3 |

| 1 1/2 | 5 | 2 7/8 | 11/16 | 2 9/16 | 7/8 | 7/8 | 4 | 5/8 | 3 7/8 | 3 |

| 2 | 6 | 3 5/8 | 3/4 | 3 7/16 | 1 | 1 | 4 | 3/4 | 4 3/4 | 5 |

| 2 1/2 | 7 | 4 1/8 | 7/8 | 3 9/16 | 1 1/8 | 1 1/8 | 4 | 3/4 | 5 1/2 | 7 |

| 3 | 7 1/2 | 5 | 15/16 | 4 1/4 | 1 3/16 | 1 3/16 | 4 | 3/4 | 6 | 8 |

| 3 1/2 | 8 1/2 | 5 1/2 | 15/16 | 4 13/16 | 1 1/4 | 1 1/4 | 8 | 3/4 | 7 | 11 |

| 4 | 9 | 6 3/16 | 15/16 | 5 5/16 | 1 5/16 | 1 5/16 | 8 | 3/4 | 7 1/2 | 13 |

| 5 | 10 | 7 5/16 | 15/16 | 6 7/16 | 1 7/16 | 1 7/16 | 8 | 7/8 | 8 1/2 | 15 |

| 6 | 11 | 8 1/2 | 1 | 7 9/16 | 1 9/16 | 1 9/16 | 8 | 7/8 | 9 1/2 | 19 |

| 8 | 13 1/2 | 10 5/8 | 1 1/8 | 9 11/16 | 1 3/4 | 1 3/4 | 8 | 7/8 | 11 3/4 | 30 |

| 10 | 16 | 12 3/4 | 1 3/16 | 12 | 1 15/16 | 1 15/16 | 12 | 1 | 14 1/4 | 43 |

| 12 | 19 | 15 | 1 1/4 | 14 3/8 | 2 3/16 | 2 3/16 | 12 | 1 | 17 | 64 |

| 14 | 21 | 16 1/4 | 1 3/8 | 15 3/4 | 2 1/4 | 2 1/4 | 12 | 1 1/8 | 18 3/4 | 85 |

| 16 | 23 1/2 | 18 1/2 | 1 7/16 | 18 | 2 1/2 | 2 1/2 | 16 | 1 1/8 | 21 1/4 | 93 |

| 18 | 25 | 21 | 1 9/16 | 19 7/8 | 2 11/16 | 2 11/16 | 16 | 1 1/4 | 22 3/4 | 120 |

| 20 | 27 1/2 | 23 | 1 11/16 | 22 | 2 7/8 | 2 7/8 | 20 | 1 1/4 | 25 | 155 |

| 22 | 29 1/2 | 25 1/4 | 1 13/16 | 24 | 3 1/8 | 3 1/8 | 20 | 1 3/8 | 27 1/4 | 159 |

| 24 | 32 | 27 1/4 | 1 7/8 | 26 1/8 | 3 1/4 | 3 1/4 | 20 | 1 3/8 | 29 1/2 | 210 |

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.