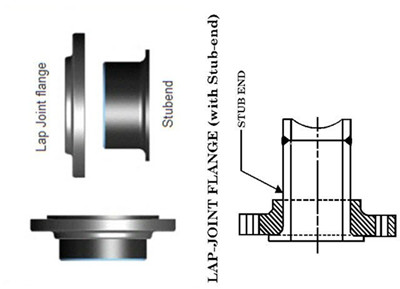

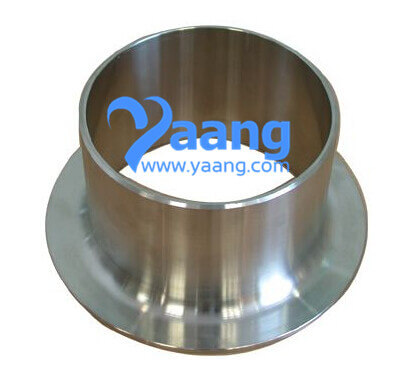

Description Of ASTM B366 UNS N06022 Hastelloy C22 Stub End

Type |

Hastelloy C22 Stub End |

Size |

1/2" To 48" (DN15-1200) |

Wall thickness |

sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, etc |

Standards |

ASME, ASTM, DIN, JIS, etc |

Material |

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc |

Surface treatment |

Transparent oil, rust-proof black oil or hot galvanized |

Applications |

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |