Packaging & Delivery

| Packaging Details: | Plywood case or fumigated woodern case or as per customers' requests. |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

PRODUCTS

Credibility ,

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

| Packaging Details: | Plywood case or fumigated woodern case or as per customers' requests. |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

4.Standard: ASME, JIS, DIN, ANSI, etc.

UNS N10276 Hastelloy C276 is very useful materials for the manufacture of high quality tubing products. One of the key reasons is that they offer excellent corrosion resistance in both aqueous and high temperature applications.

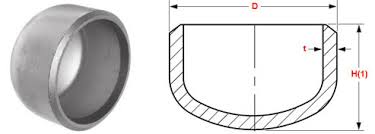

Specifications - ASTM B366 UNS N10276 Hastelloy C276 Pipe Cap

| ASTM | B619, B366, B564 |

| ASME | SB619, SB366, SB564 |

Chemical Composition - ASTM B366 UNS N10276 Hastelloy C276 Pipe Cap

| C | Co | Cr | Fe | Mn | Mo | Ni | P | S | Si | V | W |

| Max | Max | Max | Max | Max | Max | Max | |||||

| 0.01% | 2.5% | 14.5% -16.5% |

4-7% | 1.0% | 15 -17% | BAL | .04% | 0.03% | 0.08% | 0.35% | 3-4.5% |

Mechanical & Physical Properties Of ASTM B366 UNS N10276 Hastelloy C276 Pipe Cap

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

What are the characteristics of Hastelloy C276?

1、Excellent corrosion resistance in reducing environments

2、Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

3、High nickel and molybdenum contents providing good corrosion resistance in reducing environments

4、Low carbon content which minimizes grain-boundary carbide precipitation during welding to in heat-affected zones of welded joints

5、Resistance to localized corrosion such as pitting and stress-corrosion cracking

6、One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Design Features - UNS N10276 Hastelloy C276

1、Outstanding corrosion resistance and oxidizing environments.

2、Excellent resistance to pitting and stress-corrosion cracking.

3、Maintains corrosion resistance in welded joints.

Application of ASTM B366 UNS N10276 Hastelloy C276 Pipe Cap

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

5. Oil and Gas Pipeline industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

Pipe Cap is a type of pipe fitting, usually liquid or gas tight, which covers the end of a pipe. A pipe cap is used like plug, except that the pipe cap screws or attaches on the male thread of a pipe. A pipe cap may have a solvent weld socket end or a female threaded end and the other end closed off. In plumbing systems that use threads, the cap has female threads. Industrial caps can be round, square, rectangular, U-shaped, I-shaped and may have a round hand grip or a flat hand grip.

If a solvent weld pipe cap is used to provide for a future connection point, several inches of pipe must be left before the pipe cap. This is because when the pipe cap is cut off for the future connection, enough pipe must remain to allow a new fitting to be glued onto it.

If any inquiry, please feel free to contact by email [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.