- SITEMAP

- CONTACT US

- 8618267732328

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

Bset Price A312 TP321 Seamless Stainless Steel Pipes

- FOB PriceUSD 8,00- 30,000/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece/Ton

- Supply Ability1000 Tons Per Month

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery7- 20 days

Quick Details

| Standard: | ASTM, AISI, DIN, EN, GB, JIS

|

Place of Origin: | Zhejiang, China (Mainland)

|

Brand Name: | |

| Material: | 304, 316L, 321, etc

|

Type: | Seamless Stainless Steel Pipes

|

Welding Line Type: | ERW

|

| Application: | petroleum,

chemical instrumentation,

industrial pipeline,etc

|

Processing method: | cold rolled/hot rolled/cold drawn

|

Length: | 1-6m or

as per your request

|

| Thickness: | 0.5mm - 100mm

|

Outer Diameter: | 6mm - 115 mm or

as per your request

|

Packaging & Delivery

| Packaging Detail: | Standard export packing or as per request |

| Delivery Detail: | 7 - 20 days after 30% deposit |

Specifications

Bset Price A312 TP321 Seamless Stainless Steel Pipes

1. Thickness: 0.5mm - 100mm

2. Diameter: 6mm - 115mm

3. Type: Seamless Stainless Steel Pipes

| Name | Bset Price A312 TP321 Seamless Stainless Steel Pipes |

| Specification | Diameter: 6mm~115mm or as per your request Width: 0.5mm-100mm Length: 1m-6m or as per your request |

| Property | Plain End/ Bevel End; Fix |

| Duplex stainless steel | S32750, S31803, S31500, SAF2507, SAF2205,etc |

| Material | 201/202/301/302/303/304/304L/304H/304N/305/309/309S/310S/316 316L/316Ti/316N/316LN/317/317L/321/321H/347/347H/408/409/410 416/420/430/436/439/440/441/443/444/620/630/904L, etc |

Processing method |

cold rolled/hot rolled/cold drawn |

| Surface treatment | NO1, NO2D, NO2B, BA, NO4, NO240, HL, NO8 |

| Standard | GB/T4237-2009; GB/T4238-2009; GB/T3280-2007 ; GB/T4237-2007 JIS G4304-2005 ; JIS G4305-2005 ; ASTM A240/240M-10; ASTM A240-05 |

| Application | Particularly applicable to draw straws,

Used for solid such as powder, clastic and granular objects

Used in gas medium

Used in industrial dust removal and pumping equipment, air conditioning and ventilation system

Used as durable protection tube

Used in the manufacture of machinery parts and engineering structures

For a variety of conventional weapons, gun, ammunition

|

Introduce

Stainless steel pipe is a hollow long round steel, the main is widely used in petroleum, chemical, medical, food, light industry,

machinery, instrument, such as industrial pipeline and mechanical structure parts, etc.

Also commonly used for the production of various kinds of conventional weapons, barrel, shells, etc.

Advantages

Stainless steel is much stronger than any particular kinds of metal. Stainless steel pipes/tubes – it owns durability,

heat resistance, corrosion resistance and pressure resistance.

So, it also looks aesthetically acceptable. Polished inner surface of tubes allow passing any liquid, for example,

alkali and acid, gasoline, and cleaning water, milk and alcohol and thus there are no chemical reaction with the walls of the pipes.

Chemical Composition

| Grade | Chemical Composition | ||||||||

| C max | Si max | Mn max | P max | S max | Ni | Cr | Mo | Others | |

| TP 304 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 8 - 11 | 18 - 20 | ||

| TP 304L | 0.035 | 0.75 | 2 | 0.04 | 0.03 | 8 - 13 | 18 – 20 | ||

| TP 310S | 0.08 | 0.75 | 2 | 0.045 | 0.03 | 19 - 22 | 24 -26 | 0.75 max | |

| TP 316 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 10 - 14 | 16 – 18 | 2 – 3 | |

| TP 316L | 0.035 | 0.75 | 2 | 0.04 | 0.03 | 10 - 15 | 16 - 18 | 2 - 3 | |

| TP 317 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 11 - 14 | 18 - 20 | 3 - 4 | |

| TP 321 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 9 - 13 | 17 - 20 | Ti: 5×C% | |

Mechanical property

| Mechanical Properties | |||||

| Grade | Tensile Strength Mpa, (Min) |

Yield Strength Mpa, (Min) |

%Age Elongation in 50mm gauge length min |

Hardness (Max) | |

| BHN | RB | ||||

| 301 | 585 | 244 | 56 | 197 | 75 |

| 304 | 585 | 244 | 56 | 191 | 72 |

| 304L | 585 | 210 | 56 | 191 | 72 |

| 310S | 615 | 245 | 56 | 197 | 75 |

| 316 | 615 | 245 | 57 | 197 | 75 |

| 316L | 585 | 215 | 56 | 197 | 75 |

| 321 | 615 | 245 | 56 | 197 | 75 |

If any inquiry about products, please feel free to contact us [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

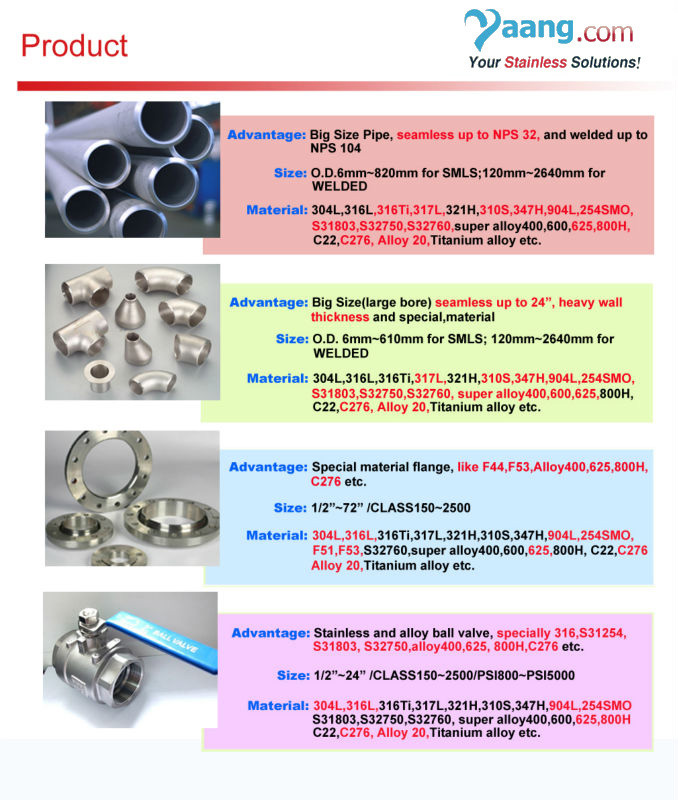

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.