- SITEMAP

- CONTACT US

- 8618267732328

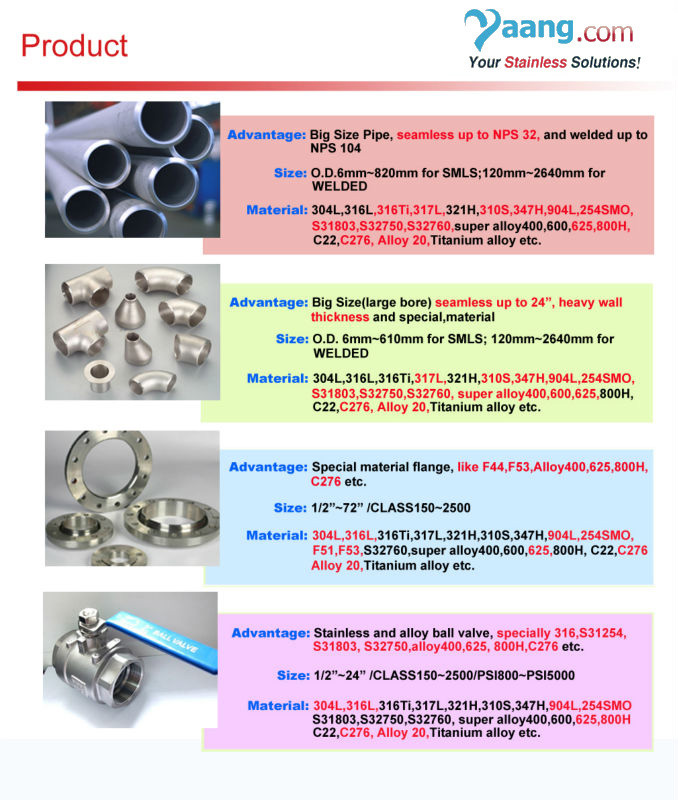

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

Incoloy 926 flange

- FOB PriceUSD 1 - 1,600/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability200 Tons per Month

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 15 days

Quick Details

| Place of Origin: |

ZheJiang, China (Mainland) |

Application: |

Fire system

|

Grade: |

incoloy 926

|

| Ni (Min): |

24

|

Powder Or Not: |

Not Powder

|

Ultimate Strength (≥ MPa): |

650

|

| Elongation (≥ %): |

35

|

Model Number: |

926

|

Brand Name: | |

| wire: |

high temperature

|

Packaging & Delivery

| Packaging Details: | wooden cases, pallet or according to clients' requirements |

|---|---|

| Delivery Detail: | 2 - 15 days or negotiable |

Specifications

Incoloy 926 flange

Diameter:12-300mm

Density : 8.1g/cm3

Materials: Inconel 600, 601, 625, 718, X750, Incoloy 901, 925, monel400, etc

Incoloy 926 Chemical composition

| Alloy | % |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Mo |

N |

Ti |

P |

S |

926 |

Min. |

24 |

19 |

Balance |

|

|

|

0.5 |

6.0 |

0.15 |

0.6 |

|

|

Max. |

26 |

21 |

0.02 |

2 |

0.5 |

1.5 |

7.0 |

0.25 |

1.2 |

0.03 |

0.01 |

Incoloy 926 Physical properties

| Density | 8.1 g/cm3 |

Melting point |

1320-1390 °C |

Incoloy 926 Alloy Minimum Mechanical properties in the room temperature

| Alloy state | Tensile strength |

Yield strength |

Elongation |

926 |

650 |

295 |

35 |

1.It has high resistance to pitting and crevice corrosion when in Halide and H2S contained acid media.

2.In practice, effective in resistance of chloride stress corrosion cracking.

3.A variety of corrosion have good corrosion resistance capability in the normal oxidation and restore environment.

4.Upgrade mechanical properties than Cronifer 1925 LC-Alloy 904 L.

5. Alloys has Improved the stability of metallurgical compared to a range of 18% of the nickel content alloys.

6.With a certification of applied in manufacturing-related pressure vessel (VdTUV-196~400°C and ASME )

Metallurgical structure

Incoloy 926 is face-centered cubic lattice structure.

Corrosion resistance

Incoloy 926 is an austenitic stainless steel alloy has a similar chemical composition with 904L alloy, its nitrogen content is 0.2%, molybdenum content is 6.5%. Molybdenum and nitrogen content significantly increased the resistance of pitting and crevice corrosion in the halide media.Meantime, nickel and nitrogen not only ensures the stability of metallographical, but also reduce separating intergranular trend in the thermal process or welding process better than the nitrogen content of nickel alloy. 926 has particular corrosion resistance in the chloride ions medium due to the excellent local corrosion resistance and 25% nickel alloy content.A variety of experiments in the 10000-70000ppm of Chloride concentration, PH 5-6, 50-68°C operating temperature of the slurry of limestone FGD system show that, after a 1-2 year trial period, 926 alloy without pitting and crevice corrosion.926 in other chemical media also has good corrosion resistance in the high temperature and high concentration of media, including sulfuric acid, phosphoric acid, acid gas, sea water, salt and organic acids.926 is the material that choosed for BAM directory Chapter 6 of "dangerous goods storage and transportation containers norms" by Berlin, Germany's national Institute for Materials Research and Testing (BAM) . In addition, in order to have the best corrosion resistance only when the material is in the right state of metallurgy and guarantee clean conditions.

Application field

Alloy 926 is a multipurpose material can be applied in many industrial:

1. Fire system, water purification system, marine engineering and hydraulic piping perfusion system

2. The pipeline, joint, air systems in the acidic gas production

3. Evaporator, the heat exchanger, filter, mixer, etc. in the phosphate production

4.Power plants condensation and pipe system in the use of sewage water to cool water

5. The use of acidic organic catalyst chlorinated derivatives production

6. The production of cellulose pulp bleacher

7. Polished bar in the orrosive oil wells

8. Hose system in the ocean engineering

9. Flue gas desulphurization system components

10. Sulfuric acid condensation and separation system

11. Crystalline salt concentration and the evaporator

12. Transport of corrosive chemicals containers

13. Reverse osmosis desalination plant

If any inquiry about products, please feel free to contact us [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.