Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 15 days after receiving the deposit |

PRODUCTS

Credibility ,

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 15 days after receiving the deposit |

3. Standard: ANSI B16.5

4. Type: Nickel Alloy 200/201 WN RF Flange

5. Pressure: 600#

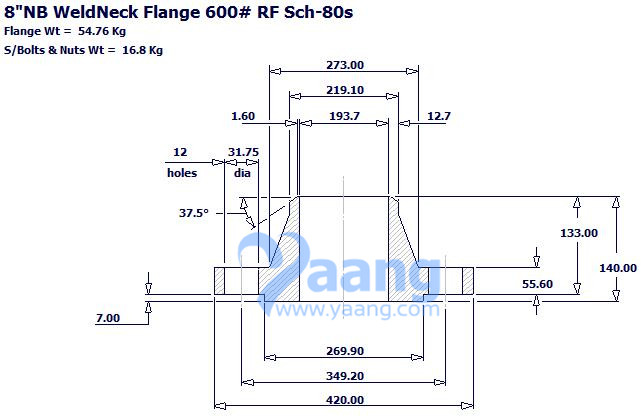

China Flange Manufacturer Yaang supplies ANSI B16.5 ASTM B564 Nickel Alloy 200/201 WN RF Flange, 8 Inch, SCH80S, CL600.

Nickel 200 and Nickel 201 are solid solution strengthened, commercially pure wrought materials. Typically, the elemental restrictions of both alloys are combined into one, dual-certified chemistry resulting in a single alloy with the desired characteristics of both alloys. Applications where Nickel 200/201 can be used include chemical processing and storage, synthetic fiber production, and processes where sodium hydroxide and fluorine is used. Other applications include aerospace and defense as well as food processing. Nickel 200/201 has exceptional resistance to caustic alkalies at various temperatures and concentrations.

When operating temperatures are expected to exceed 600°F, carbon content becomes critical. The lower carbon content of Nickel 201 makes the material resistant to graphitization and therefore less subject to embrittlement. Pressure vessels and vessel components can be constructed from Nickel 201 according to the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 for use up to 1250°F.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Nickel 200 | N02200 | 2.4066 | N-100M | Ni 99.2 | NW 2200 | NA 11 | НП-2 |

| Nickel 201 | N02201 | 2.4068 | - | LC-Ni 99 | NW 2201 | NA 11 | НП-2 |

| Grade | NI | FE | CU | C | MN | S | SI |

| Nickel Alloy 200 | 99.0 min | .40 max | .25 max | .15 max | .35 max | .01 max | .35 max |

| NI | FE | CU | C | MN | S | SI | |

| Nickel Alloy 201 | 99.0 min | .40 max | .25 max | .02 max> | .35 max | .01 max | .35 max |

| Grade | Density | Yield Strength (0.2%Offset) | Tensile Strength | Elongation | Melting Point |

| Nickel Alloy 200 / 201 | 8.9 g/cm3 | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % | 1446 °C (2635 °F) |

| Nickel Alloy 200/201 WNRF Flange 8 Inch SCH80S CL600 | ||

| 1 | Material: | Stainless Steel: such as 304, 304L, 316, 316L, 321 , 310S, 904L, S31803, F51 and so on. |

| 2 | Standard: | GB, JIS, BS, DIN, ANSI and Non standard |

| 3 | ANSI Class: | 15, 030, 040, 060, 090 |

| 4 | Size: | 1/2" - 24" |

| 5 | Type: | Slip-on flanges, Blind flanges, Lap joint flanges, Welding neck flanges,Plate flange, Socket welding flanges and Treaded flanges |

| 6 | Pressure ratings: | Class: 150 300 400 600 900 1500 and 2500 PN: 6 10 16 25 40 64 and 160 , 5K - 40K and so on |

| 7 | Sealing surface: | FF ,RF, LJ, FM , R.T.J , R.J and so on . |

| 8 | Production process: | raw material-cutting-heating-forging-heat treatment-maching-inspection. |

| 15 | Application: | petroleum, chemical, power, gas, water, linepipe, heat exchanger, shipbuilding, construction, etc. |

| 16 | Tolerance: | not less than +_8% of normal wall thickness. |

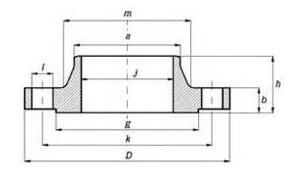

| ANSI/ASME/ASA B16.5 600lb/sq.in. WELDING NECK FLANGE RF | |||||||||||

| ø | D | b | g | m | a | J* | h | k | Holes | l | Kg. |

| 1/2" | 95,2 | 14,3 | 34,9 | 38,1 | 21,3 | 15,7 | 52,4 | 66,7 | 4 | 15,9 | 0,900 |

| 3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 26,7 | 20,9 | 57,1 | 82,5 | 4 | 19,0 | 1,500 |

| 1" | 123,8 | 17,5 | 50,8 | 54,0 | 33,5 | 26,7 | 61,9 | 88,9 | 4 | 19,0 | 1,900 |

| 1 1/4" | 133,3 | 20,6 | 63,5 | 63,5 | 42,2 | 35,0 | 66,7 | 98,4 | 4 | 19,0 | 2,600 |

| 1 1/2" | 155,6 | 22,2 | 73,0 | 69,8 | 48,3 | 40,9 | 69,8 | 114,3 | 4 | 22,2 | 3,300 |

| 2" | 165,1 | 25,4 | 92,1 | 84,1 | 60,3 | 52,6 | 73,0 | 127,0 | 8 | 19,0 | 4,700 |

| 2 1/2" | 190,5 | 28,6 | 104,8 | 100,0 | 73,1 | 62,7 | 79,4 | 149,2 | 8 | 22,2 | 6,500 |

| 3" | 209,5 | 31,7 | 127,0 | 117,5 | 88,9 | 78,0 | 82,5 | 168,3 | 8 | 22,2 | 8,700 |

| 3 1/2" | 228,6 | 34,9 | 139,7 | 133,3 | 101,6 | 90,1 | 85,7 | 184,1 | 8 | 25,4 | 11,200 |

| 4" | 273,0 | 38,1 | 157,2 | 152,4 | 114,3 | 102,4 | 101,6 | 215,9 | 8 | 25,4 | 18,100 |

| 5" | 330,2 | 44,4 | 185,7 | 188,9 | 141,2 | 128,2 | 114,3 | 266,7 | 8 | 28,6 | 30,500 |

| 6" | 355,6 | 47,6 | 215,9 | 222,2 | 168,4 | 154,2 | 117,5 | 292,1 | 12 | 28,6 | 36,200 |

| 8" | 419,1 | 55,6 | 269,9 | 273,0 | 219,1 | 202,7 | 133,3 | 349,2 | 12 | 31,7 | 56,500 |

| 10" | 508,0 | 63,5 | 323,8 | 342,9 | 273,0 | 254,5 | 152,4 | 431,8 | 16 | 34,9 | 91,000 |

| 12" | 558,8 | 66,7 | 381,0 | 400,0 | 323,8 | 304,8 | 155,6 | 488,9 | 20 | 34,9 | 105,000 |

| 14" | 603,2 | 69,8 | 412,7 | 431,8 | 355,6 | * | 165,1 | 527,0 | 20 | 38,1 | 125,000 |

| 16" | 685,8 | 76,2 | 469,9 | 495,3 | 406,4 | 177,8 | 603,2 | 20 | 41,3 | 178,000 | |

| 18" | 742,9 | 82,5 | 533,4 | 546,1 | 457,2 | 184,1 | 654,0 | 20 | 44,4 | 261,000 | |

| 20" | 812,8 | 88,9 | 584,2 | 609,6 | 508,0 | 190,5 | 723,9 | 24 | 44,4 | 268,000 | |

| 22" | 869,9 | 95,2 | 641,2 | 666,7 | 558,8 | 196,8 | 777,9 | 24 | 47,6 | 328,000 | |

| 24" | 939,8 | 101,6 | 692,1 | 717,5 | 609,6 | 203,2 | 838,2 | 24 | 50,8 | 380,000 | |

| * | The data "J" corresponds to the STD schedule | ||||||||||

| To be specifiedby customer | |||||||||||

NOTE:

1. Class 600 flanges except Lap Joint will be furnished with 0.25 (6.35mm) raised face, which is not included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3). 2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees. 3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub. 4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C). 5. Dimensions of sizes 1/2 through 3 1/2 are the same as for Class 400 Flanges. 6. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option. 7. Welding Neck Flange Bore Size SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100, SCH 120, SCH140, SCH160, XS |

APPLICATIONS:

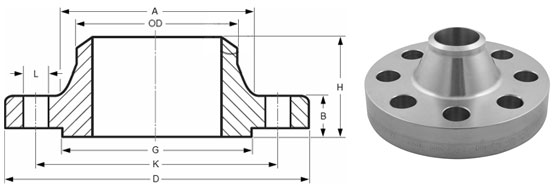

Weld neck flange is a type of pipe flange that incorporates a cast-in neck that is welded to the pipe. Unlike a plain flange that is slipped over the pipe prior to being welded into place, a weld neck flange has a spout-like neck that is beveled to match up to the pipe. Once the pipe is beveled to match the weld neck flange, a perfect V shape is created in which a butt weld is placed to connect the two components.

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

If any inquiry about products, please feel free to contact us [email protected]

PT - PENETRATION TESTING

This method is used for detection of welding discontinuities (material discontinuities) appearing on the surface of a welded connector. This test is done following a visual testing of a welded connector and used mainly for both ferromagnetic and non-ferromagnetic materials.

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.