Composition ranges for 316L stainless steel

- SITEMAP

- CONTACT US

- 8618267732328

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

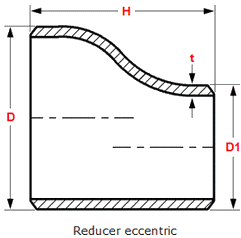

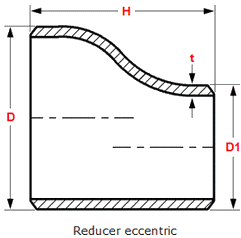

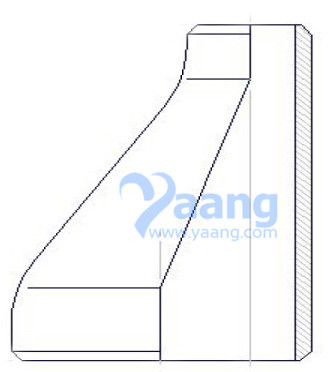

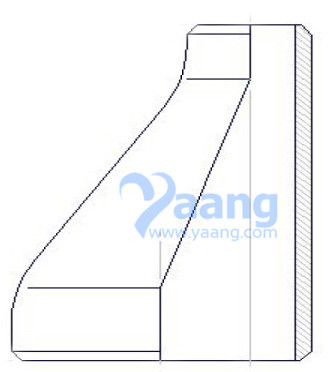

ANSI B16.9 ASTM A403 WP316L Eccentric Reducer DN100 - DN40 SCH10S

- FOB PriceUSD 1 - 1,700/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Pieces Per Day

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 10 days

Quick Details

- Material: 316L

- Technics: Cold Forming

- Type: 316L Eccentric Reducer

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Yaang

- Connection: Welding

- Shape: Equal, Reducing, etc

- Head Code: Round

- Standard: ASTM A403, etc

- Size: DN100 - DN40

- Surface: Sand Rolling, Sand Blasting, Polishing

- Application: Oil, Gas, Etc

- Special Desgin: Available

Packaging & Delivery

Packaging Detail:

wooden cases or PPwrapping with bundles as customer's required

Delivery Detail:

2 - 10 days

| Packaging Detail: | wooden cases or PPwrapping with bundles as customer's required |

| Delivery Detail: | 2 - 10 days |

Specifications

ANSI B16.9 ASTM A403 WP316L Eccentric Reducer

1. Material: 316L

2. Technics: Cold Forming

3. Type: 316L Eccentric Reducer

4. Size: DN100 - DN40

WT: Sch10s

China Reducer Manufacturer Yaang supplies ANSI B16.9 ASTM A403 WP316L Eccentric Reducer, DN100 - DN40, SCH10S.

NPS

O.D.

D

O.D.

D1

Len

H

4*1½

114.3

48.3

102

ANSI B16.9 ASTM A403 WP316L Eccentric Reducer

1. Material: 316L

2. Technics: Cold Forming

3. Type: 316L Eccentric Reducer

4. Size: DN100 - DN40

WT: Sch10s

China Reducer Manufacturer Yaang supplies ANSI B16.9 ASTM A403 WP316L Eccentric Reducer, DN100 - DN40, SCH10S.

| NPS | O.D. D |

O.D. D1 |

Len H |

| 4*1½ | 114.3 | 48.3 | 102 |

Grade |

|

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

316L |

Min |

- |

- |

- |

- |

- |

16.0 |

2.00 |

10.0 |

- |

Max |

0.03 |

2.0 |

0.75 |

0.045 |

0.03 |

18.0 |

3.00 |

14.0 |

0.10 |

Grade specifications for 316L stainless steel

Grade |

UNS |

Old British |

Euronorm |

Swedish |

Japanese |

||

BS |

En |

No |

Name |

||||

316L |

S31603 |

316S11 |

- |

1.4404 |

X2CrNiMo17-12-2 |

2348 |

SUS 316L |

Type

WP316L Eccentric Reducer

Size

Seamless: 1/2" - 24"; welded: 8" - 100"

Wall thickness

SCH 5,SCH 10,SCH 20,SCH 40,SCH 80,SCH 120,SCH 160,SCH XXS

Standards

ANSI, ASTM,DIN, JIS, etc

Material

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Super Duplex Stainless Steel: S32750/2507, UNS32760, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Surface treatment

Transparent oil, rust-proof black oil or hot galvanized

Applications

Petroleum, chemical, power, gas, metallurgy,

shipbuilding, construction, etc

An eccentric reducer is manufactured with the smaller outlet off center to the larger end, which allows it to align with only one side of the inlet. The eccentric reducer must be installed with straight side up so that it can prevent trapping air at the pump suction. The eccentric reducers allow simple connection of different sized pipes.

Applications of 316L Eccentric Reducer:

Type |

WP316L Eccentric Reducer |

Size |

Seamless: 1/2" - 24"; welded: 8" - 100" |

Wall thickness |

SCH 5,SCH 10,SCH 20,SCH 40,SCH 80,SCH 120,SCH 160,SCH XXS |

Standards |

ANSI, ASTM,DIN, JIS, etc |

Material |

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Super Duplex Stainless Steel: S32750/2507, UNS32760, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc |

Surface treatment |

Transparent oil, rust-proof black oil or hot galvanized |

Applications |

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

An eccentric reducer is manufactured with the smaller outlet off center to the larger end, which allows it to align with only one side of the inlet. The eccentric reducer must be installed with straight side up so that it can prevent trapping air at the pump suction. The eccentric reducers allow simple connection of different sized pipes.

Applications of 316L Eccentric Reducer:

Chemical process vessels, piping and heat exchangers

Pulp mill digesters, bleach washers, chip pre-steaming vessels

Food processing equipment

Oil field piping and heat exchangers

Flue gas desulfurization equipment

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ANSI B16.9 ASTM A403 WP316L Eccentric Reducer, DN100 - DN40, SCH10S.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.