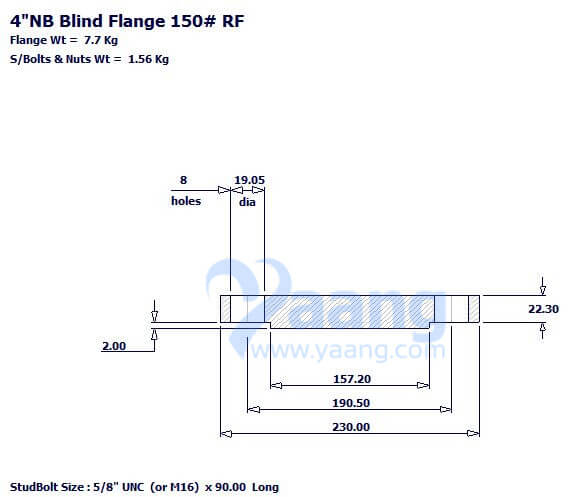

1. Material: Inconel 718 (UNS N07718)

2. Size: 4" (DN100)

3. Standard: ASME B16.5

4. Pressure: 150#

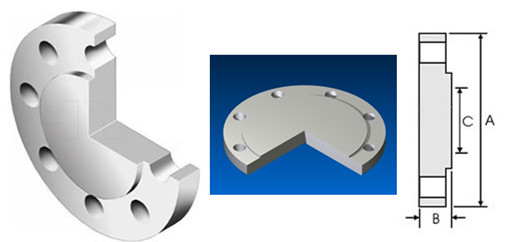

A blind flange is a solid disk used to block off a pipeline or to create a stop. It is machined in the same manner as a regular flange with the mounting holes around the perimeter and the gasket sealing rings machined into the mating surface. The difference is that a blind flange has no opening to allow fluid to pass through. The blind flange can be inserted between two open flanges and used to block off the flow of liquid through a pipeline.

Without the blind flange it would be difficult to perform maintenance or repairs on a pipeline. The flow would need to be shut off at the nearest valve, which could be miles away from the repair area. Valves are also very expensive and are prone to sticking. The blind flange is a much more cost efficient way of sealing a pipe.

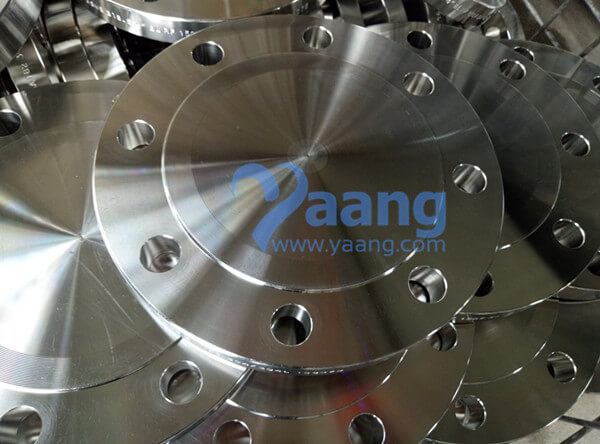

China Blind Flange Manufacturer Yaang supplies ASME B16.5 ASTM B564 Inconel 718 Blind Flange, 4 Inch, Class150.