Quick Details

| Material: |

316L (1.4404)

|

Technics: |

Forged

|

Type: |

Reducing Tee |

| Place of Origin: |

Zhejiang, China (Mainland)

|

Model Number: |

Reducing Tee

|

Brand Name: |

Yaang

|

| Connection: |

Welding, Weld

|

Shape: |

Equal

|

Head Code: |

Round

|

Packaging & Delivery

| Packaging Detail: |

Plywood case or fumigation wooden case |

| Delivery Detail: |

Usually 2-10 days depend on the quantity |

Specifications

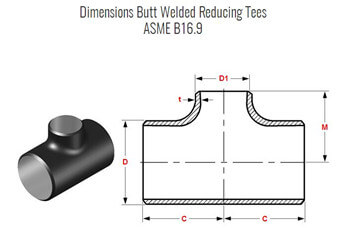

ASME B16.9 ANSI 316L (1.4404) Reducing Tee

1) Size: DN1000/900X8mm

2) THK: SCH10

3) Material: 316L (1.4404)

ASME B16.9 ANSI 316L (1.4404) Reducing Tee, like all pipe tees, is in the shape of T with two ends of equal size and the third one slightly smaller. In other words, 1.4404 reducing tee is a type of pipe fitting in which the branch port size is smaller than the ports of the run. This type of pipe fitting can also consider size reduction from one of the run ports to the other.

China Reducing Tee Manufacturer Yaang supplies ASME B16.9 ANSI 316L (1.4404) Reducing Tee, DN1000, SCH10.

Composition ranges for 316L grade of stainless steels

|

|

316

|

Min

|

-

|

-

|

-

|

0

|

-

|

16.0

|

2.00

|

10.0

|

-

|

Max

|

0.08

|

2.0

|

0.75

|

0.045

|

0.03

|

18.0

|

3.00

|

14.0

|

0.10

|

316L

|

Min

|

-

|

-

|

-

|

-

|

-

|

16.0

|

2.00

|

10.0

|

-

|

Max

|

0.03

|

2.0

|

0.75

|

0.045

|

0.03

|

18.0

|

3.00

|

14.0

|

0.10

|

316H

|

Min

|

0.04

|

0.04

|

0

|

-

|

-

|

16.0

|

2.00

|

10.0

|

-

|

max

|

0.10

|

0.10

|

0.75

|

0.045

|

0.03

|

18.0

|

3.00

|

14.0

|

-

|

Mechanical properties of 316L grade stainless steels

|

|

316

|

515

|

205

|

40

|

95

|

217

|

316L

|

485

|

170

|

40

|

95

|

217

|

316H

|

515

|

205

|

40

|

95

|

217

|

Note: 316H also has a requirement for a grain size of ASTM no. 7 or coarser.

Typical physical properties for 316L grade stainless steels

|

|

8000

|

193

|

15.9

|

16.2

|

17.5

|

16.3

|

21.5

|

500

|

740

|

Grade specifications for 316L grade stainless steels

|

|

S31600

|

316S31

|

58H, 58J

|

1.4401

|

X5CrNiMo17-12-2

|

2347

|

SUS 316

|

316L

|

S31603

|

316S11

|

-

|

1.4404

|

X2CrNiMo17-12-2

|

2348

|

SUS 316L

|

316H

|

S31609

|

316S51

|

-

|

-

|

-

|

-

|

-

|

Type

|

316L Reducing Tee

|

Size

|

SMLS Elbow: 1/2"~24" (DN15 - DN600)

Welded Elbow: 1/2"~48" (DN15 - DN1200)

|

Wall thickness

|

sch10, sch20, sch30, std, sch40S, sch60,

xs, sch80, sch100, etc

|

Standards

|

ASME, ASTM, DIN, JIS, etc

|

Material

|

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

|

Surface treatment

|

Transparent oil, rust-proof black oil or hot galvanized

|

Applications

|

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

|

Application of ASME B16.9 ANSI 316L (1.4404) Reducing Tee

1. They are manufactured to be used in flow lines for gases, fluids in industrial processes, medical, construction and many other specialized applications.

2. The 316L Reducing Tee is constructed of heavy materials for rigid applications like extreme high/low temperature resistance etc.

3. The 316L Reducing Tee is specifically designed for use on process and control systems, instrumentation, and equipment used in chemical, petroleum, fluid power, electronic and pulp and paper plants.

316L is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system.This material especially suit for high temperature environments, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environments.

ASME B16.9 ANSI 316L (1.4404) Reducing Tee's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ASME B16.9 ANSI 316L 1.4404 Reducing Tee, DN1000, SCH10.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us [email protected]