- SITEMAP

- CONTACT US

- 8618267732328

PRODUCTS

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

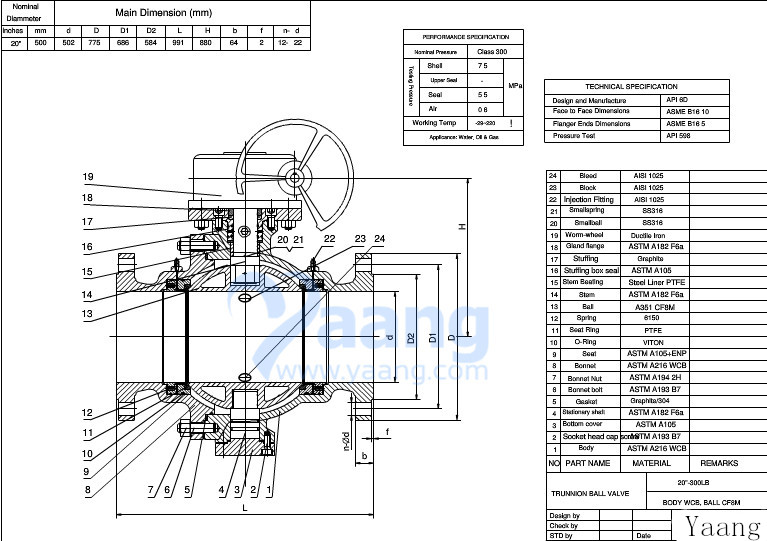

Cast Steel Trunnion Ball Valve

- FOB PriceUSD 10 - 30,000/Piece

- PortNingbo or Shanghai Port

- MOQ1 Piece

- Supply Ability1000 Tons Per Month

- Payment TermsL/C,T/T,Western Union,MoneyGram

- PackagingSeaworthy plywood cases or pallets

- Delivery2 - 12 days

Product name:Cast Steel Trunnion Ball Valve

Application: Industry, Powerstations, Flue gas purification plant, processing technology, gas supply, vapour facilities, recycling facilities, vacuum facilities, hot water, heating technology, district heating, thermal oil applications, general plant manufacturing, etc. (other applications on request)

Medium : Steam, gases, hot water, thermal fluids, hot oil, process water, vacuum facilities, ammonia etc.(other flow media on request)

Materials : WCB,SS304,SS316

Size range : 10"-24"

Class: 150LB-900LB

Temperature : ≤200 ℃

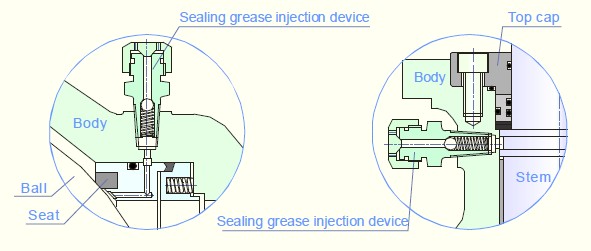

Blow-out proof stem

Blow-out proof structure is provited with for the stem, which is positioned by the up-end cap and screw, being guaranteed not to be blown-out by the medium even if at abnormal risen pressure in the cavity.

The ball of the trunnion ball valve gets close contact with each othe through the trunnion, adjusting cushion, and down-end cap, the passage of static electricity thus forms together with the valve , which may lead the static electricity caused by sparks generated by friction between the ball and seat during on and off performance to the ground to prevent the possible risk of fire or explosion.

Urgent grease injection device

According to customer s' requirement, the trunnion ball valves made by YAANG are provided with devices for urgent grease injection, which are on both the stem and seat for the trunnion ball valves of DN >150mm (NPS), and in the body cavity for the valve of DN < 125mm. When the O ring of stem or the body seat ring is damaged due to accident, the medium leakage between body and stem can be prevented by injecting the sealing grease through the device.

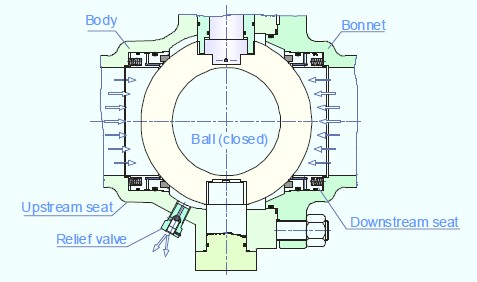

Double-block and bleed functions

In general, trunnion ball valve features the front ball sealing design structure. Each seat of the ball valve can separately cut off the medium at both inlet and outlet of the valve to realize double-block functions. When the ball valve is closed, body cavity and two of the body ends can be blocked with each other even if both the inlet and outlet are under pressure, when the medium left in the body cavity might be bled through the relief valve.

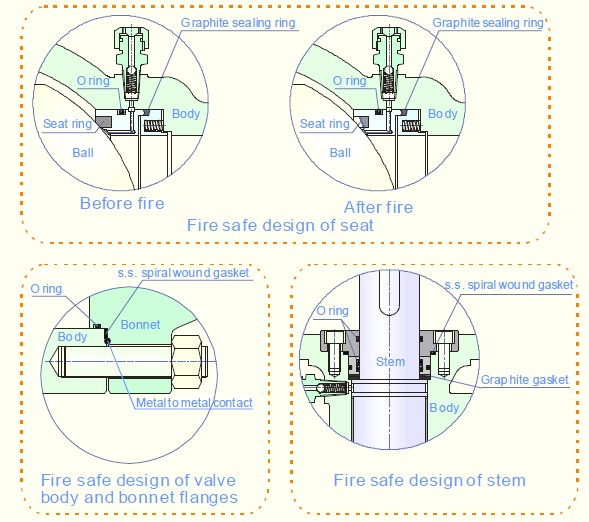

Fire safe design

With the valve heated in a fire application, the non-metal material parts such as seat sealing ring of PTFE, O ring for the stem, and sealing gasket for body and bonnet, might be damaged due to high temperature. Special design of auxiliary metal to metal or the graphite seal is provited fo rthe trunnion ball valve to effectively prevent both internal and external leakage of the valve. As required by customers, fire safe design for the trunnion ball valve meets the requirement of API 607, API 6Fa, BS 6755 and JB/T 6899.

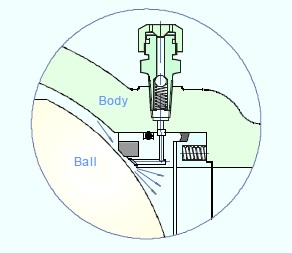

Self-relief in the body cavity

As the liquid medium left in the body cavity gasifies due to increased temperature, the pressure in the body cavity becomes abnormally higher, when the medium itself in the cavity would propel the seat and self-relieves the pressure to ensure the safety of valve.

Where can we find the high quality Cast Steel Trunnion Ball Valve.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.