Packaging & Delivery

| Packaging Detail: | Standard export packing or as per request |

| Delivery Detail: | 7 - 20 days |

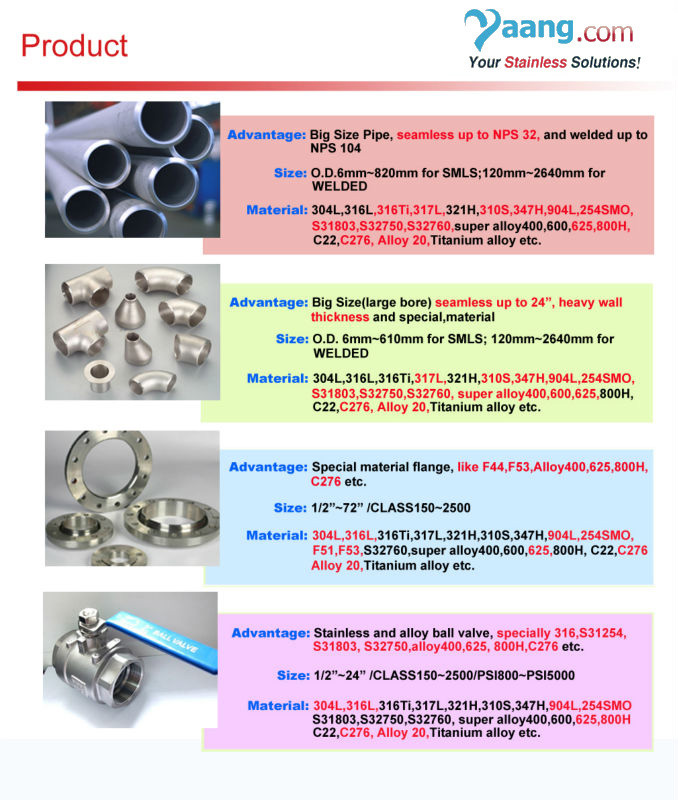

PRODUCTS

Credibility ,

ASME B16.9 ASTM A815 F51 Welded Lap Joint Stub End 14 Inch Schedule STD

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

ASME B16.5 ASTM B564 Alloy C22 WNRTJ Flange 4 Inch SCH80S CL1500

ASME B16.11 ASTM A182 GR.F316L Threaded Hex Head Plug 1 Inch CL3000

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

ASME B36.19 ASTM A213 TP347 Seamless Pipe Cold Finished 168.3 x 4.2 x 8000MM

ASME B16.5 ASTM B564 Incoloy 825 WNRTJ Flange 3 Inch SCH40S CL900

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer 4 Inch - 1-1/2 Inch SCH80

MSS-SP43 (A) ASTM A815 UNS32750 SAF2507 Stub End 3 Inch SCH80S

ASME B16.5 ASTM B564 Hastelloy C276 Blind Flange RF 80NB CL150

ASME B16.5 ASTM B564 Hastelloy C276 Socket Weld Flange 3 Inch CL150

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 45 Degree Welded Elbow LR DN609.6x4MM

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

| Packaging Detail: | Standard export packing or as per request |

| Delivery Detail: | 7 - 20 days |

TP316L SMLS pipe 16 Inch Sch40

1. Seamless

2. Thickness: SCH40

3. OD: 16 inch (DN400)

4. Lenth: 365mm

Tolerance |

a) Outer Diameter: +/- 0.1mm b) Wall Thickness: +/- 0.02mm c) Length: +/- 6mm |

Surface |

180G, 320G, 400G Satin / Hairline 400G, 500G, 600G or 800G Mirror finish and so on. |

Standard

|

AISI, ASTM, DIN, EN, GB and JIS ASTM A213,ASTM A312,ASTM A269,ASTM A778,ASTM A790 DIN 17456,DIN 17458 JIS G3459,JIS G3463 etc |

Material |

300series: 301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347 200series: 201,202,202cu,204 400series: 409,409L,410,420,430,431,439,440,441,444 Others: 2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S318039 904L,etc Duplex stainless steel: S22053,S25073,S22253,S31803,S32205,S32304 Special Stainless Steel: 904L,347/347H,317/317L,316Ti,254Mo |

Application range |

316L SMLS Pipe is widely used in below fields: 1).Petroleum,Chemical enterprise, superheater of boiler, heat exchanger 2).High temperature resistant transmission fluid pipe in power station 3).Ship with pressure pipe 4).The exhaust purification devices 5).Construction and ornament |

Main market |

We have frequenter customers from Europe: Germany,Netherland,Russia, Finland,Czech,Ukraine,Italy,Spain,Poland Middle East: Iran,UAE,SA,Iraq,Qatar,Isreal,Jordan,Bahrain,Kuwait South America: Brazil,Chile,Peru,Venezuela,Uruguay,Argentina Africa: Egypt,South Africa,Nigeria Central&North America: Mexico,US,Canada,Costa Rica South East Asia and Pacific: Japan,South Korea,Singapore,Thailand,Indonesia,Australia |

Delivery conditions |

Annealed, pickled & polished. |

Note |

We can produce other standard as the customers’ requirement. |

Chemical Composition of Material |

Material Composition |

201 |

202 |

304 |

316L |

430 |

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.035 |

≤0.12 |

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 |

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 |

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 |

|

Cr |

13-15 |

14-17 |

18-20 |

16-18 |

16-18 |

|

Ni |

0.7-1.1 |

3.5-4.5 |

8-10.5 |

10-14 |

|

|

Mo |

|

|

|

2.0-3.0 |

|

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316 |

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 |

||

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 |

||

Extension |

≥30% |

≥30% |

≥35% |

≥35% |

||

Hardness (HV) |

<105 |

<100 |

<90 |

|||

Application of TP316L SMLS pipe 16 Inch Sch40:

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

TP316L SMLS pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

TP316L SMLS pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

While marking we choose a specific item number as well different color shade to differentiate steel grades. We mark TP316L SMLS pipe as needed with the most suitable & visible marking technique.

Packaging is an integral part of the product. It guarantees that the TP316L SMLS pipe is delivered to the customer in the required quality. For smaller orders the size of the TP316L SMLS pipe bundle depends on the no. of Tubes ordered, for larger orders the tubes are packed into individual bundles and in such a way that the maximum weight of 4000kg per bundle is not excedded. Bundle tied down with steel tape. Bundle tied down by steel strap underlaid by tapaten.

We can also provide TP316L SMLS pipe wooden box packing, cardboard boxes, plastic wrapping, using hardened paper with PE meshing (used as protection against mechanical damages of tubes), into tapaten and polyethylene sheet etc.

Where can we find the high quality TP316L SMLS pipe.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

|

|

Tel No:+86-18267732328 / Email:[email protected]

Address:Longwan District, Wenzhou, Zhejiang Province, China.

Copyright Notice © www.yaang.com Yaang Pipe Industry Co., Limited All rights reserved.

Yaang Pipe Industry Co., Ltd. is an international supplier of piping solutions for flange, butt welding fittings, socket welding fittings and threaded fittings. Our products are widely used in different industrial fields, including oil and gas, chemical industry, petrochemical industry, power plant, pulp and paper industry, environmental and water conservancy engineering, engineering projects, etc.